About our stucco fence wall systems

Our products are engineered to provide security, privacy, and architectural continuity to any property.

Built in three essential elements:

Timeless, secure, and maintenance-free—our architectural stucco fencing is crafted from high-density, lightweight materials to replicate a solid stucco wall without the engineering challenges. Perfect for both commercial and residential perimeters, these systems add a powerful statement of quality and privacy.

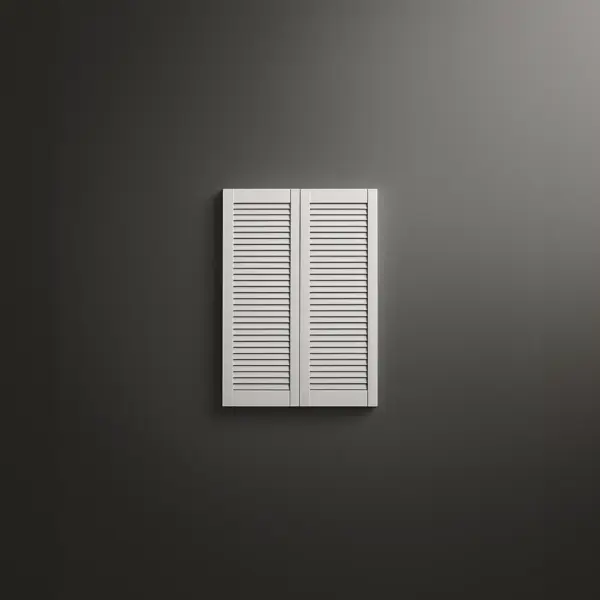

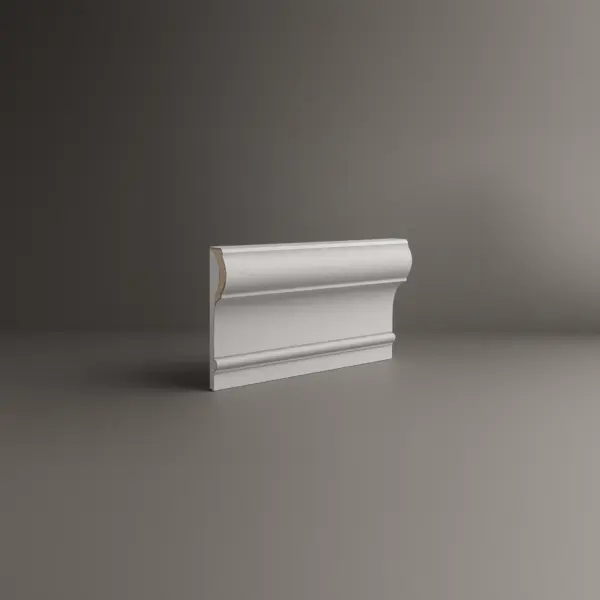

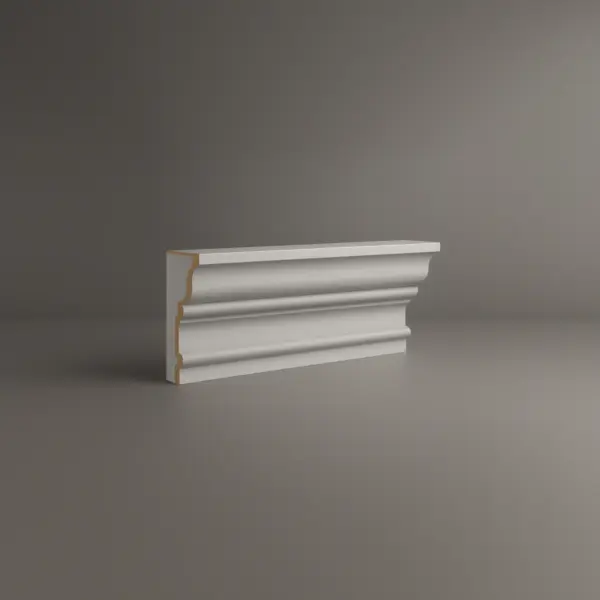

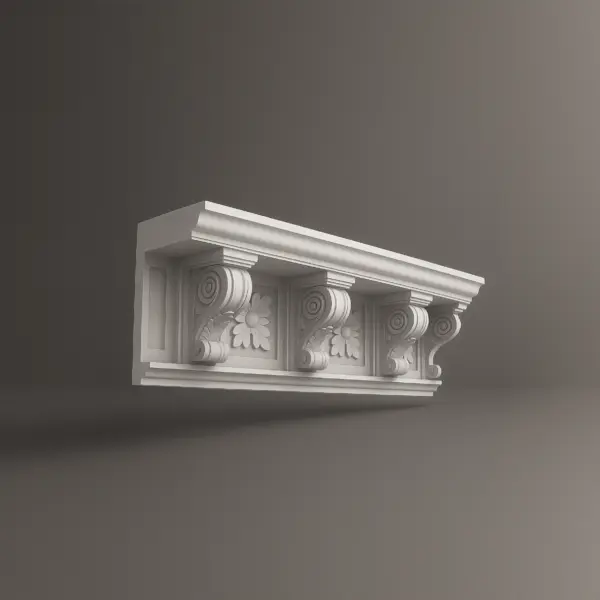

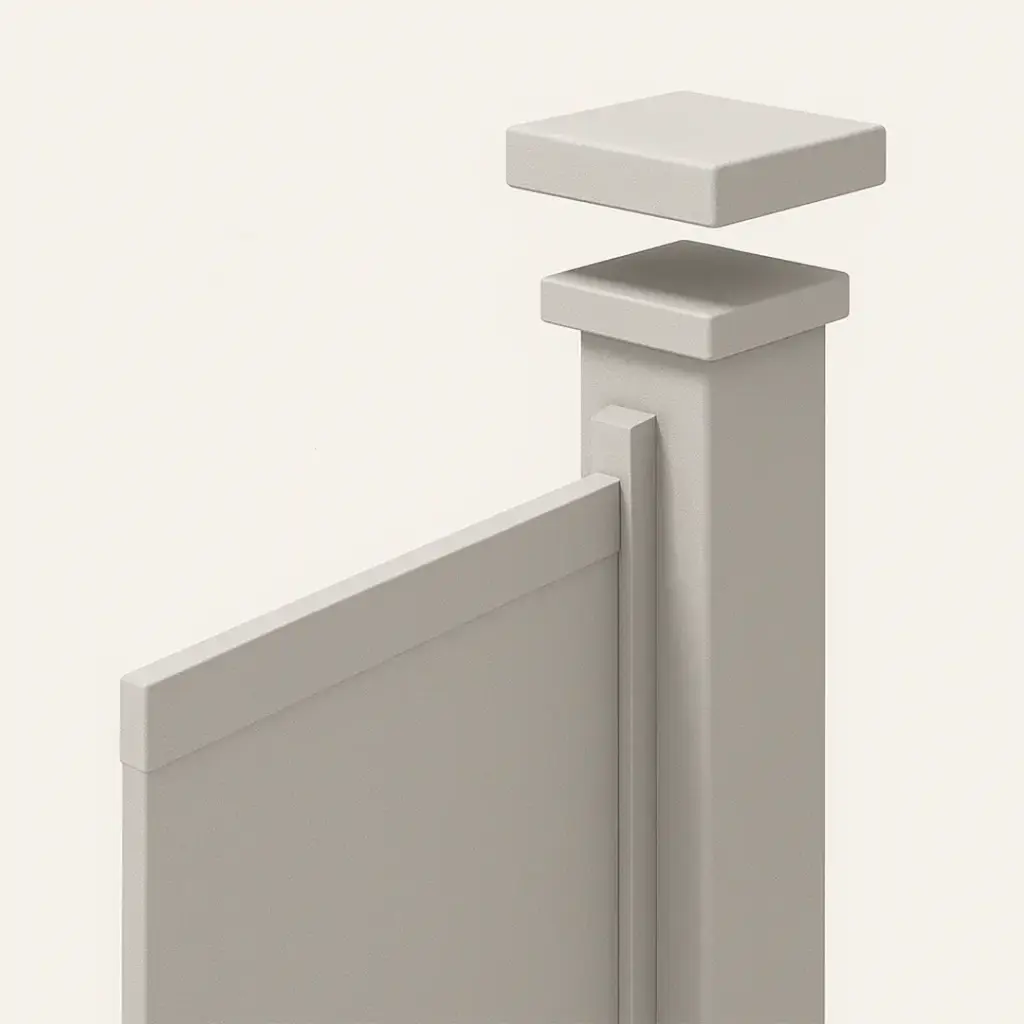

Each stucco fence wall consists of three precision-made parts:

- Post: The structural column that provides stability and defines the fence’s rhythm.

- Panel: The central stucco fence panels that form the continuous wall, available in smooth, textured, or custom-designed finishes.

- Cap: The top element that completes the design and provides protection, available in various architectural profiles.

Get a modular system that installs with precision.

The Science Behind the Strength of Our Exterior Stucco Wall

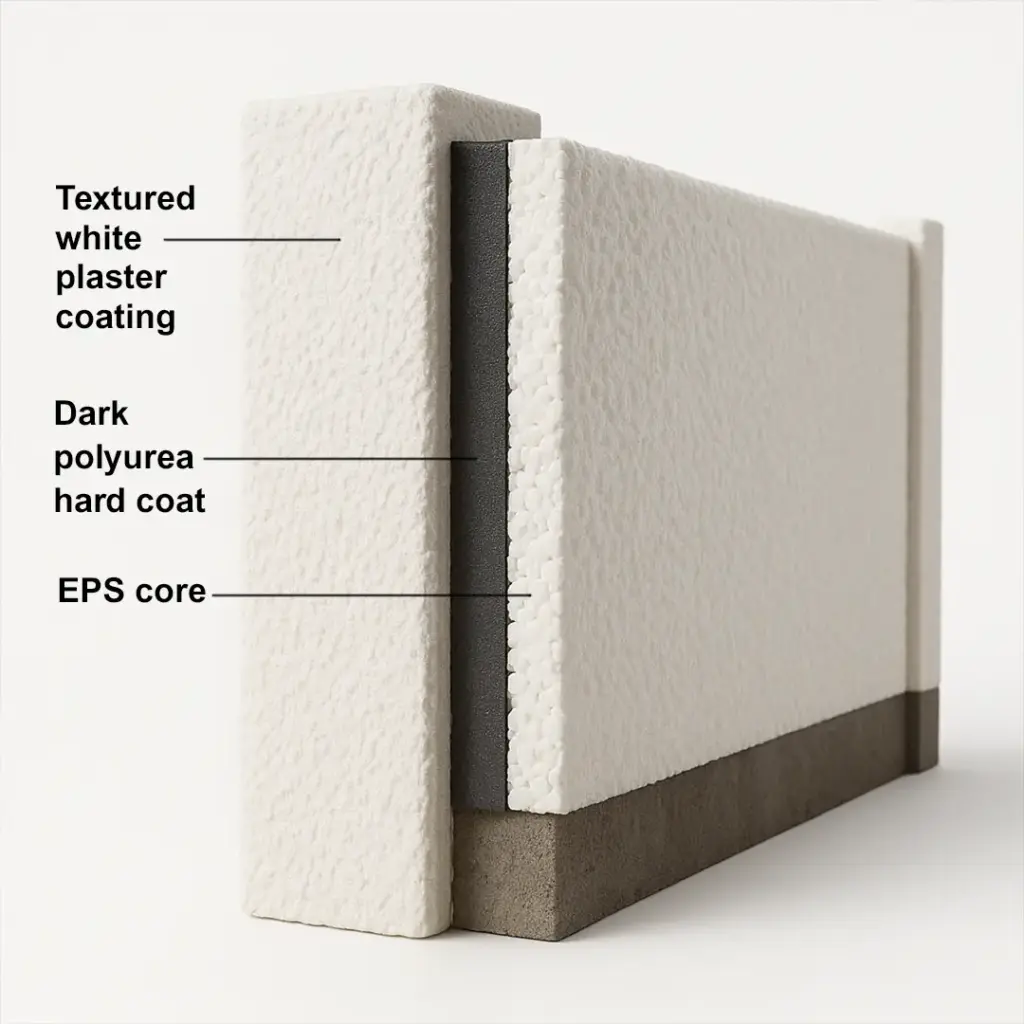

Our architectural fence systems are built from an advanced composite of materials engineered for longevity and beauty. At the core is a structural, high-density Expanded Polystyrene (EPS) foam that is precision-cut for perfect geometry.

This core is then encapsulated in our signature polyurea hard coat, a spray-applied elastomer that creates a seamless, waterproof, and impact-resistant shell. This process transforms the lightweight foam into a monolithic structure with incredible strength.

The exterior is an integrated, architectural stucco exterior wall finish that provides the authentic texture of masonry and superior resistance to weathering, UV rays, and cracking. This advanced construction makes our stucco privacy fence systems robust, elegant, and exceptionally long-lasting.

Assortment of stucco architectural fencing

EPS stucco fence vs. traditional masonry:

the Royal Foam advantage

Ready to experience the difference?

Stop settling for heavy, outdated materials. Choose a lightweight, durable, and fully customizable stucco fence—built to last, made in the USA.

Let's talk about your project today.

Discuss my projectHeavy & Labor-Intensive

Requires cranes, large crews, and extensive site prep.

Long Installation Time

Dependent on weather and long mortar curing times.

High Maintenance & Vulnerability

Prone to cracking and water damage. Requires ongoing maintenance and costly repairs.

Limited Customization

Custom shapes are extremely labor-intensive and expensive.

High Upfront & Long-Term Costs

Expensive materials, labor, and continuous upkeep.

Lightweight & Easy to Handle

Up to 90% lighter. No cranes or heavy machinery needed, drastically reducing logistics costs and jobsite complexity.

Rapid Installation

Prefabricated system minimizes on-site disruption.

Superior Durability & Low Maintenance

Crack-proof and waterproof. Virtually maintenance-free with a lifespan of 80-100 years.

Unlimited Customization

CNC technology creates any custom shape, curve, or texture.

Lower Total Cost of Ownership

Significant savings on labor, equipment, and long-term maintenance.

Сustom stucco architectural fencing

How to order architectural stucco fencing

From your initial site plan to final installation—our process is transparent, fast, and engineered for precision.

It all begins with a deep dive into your project. We work as your technical partner to translate creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your decorative architectural shapes with flawless precision, matching your approved 3D model to the millimeter.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exacting standards for form, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build custom shipping crates for your elements, ensuring they arrive on-site in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

It all begins with a deep dive into your project. We work as your technical partner to translate creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your decorative architectural shapes with flawless precision, matching your approved 3D model to the millimeter.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exacting standards for form, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build custom shipping crates for your elements, ensuring they arrive on-site in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

Our project gallery

Engineered solutions for every project

Your tasks—our solutions. For professionals who value time, budget, and results.

For Developers & HOAs

We provide standardized decorative garden fence panels for entire communities, ensuring a unified, high-end aesthetic. The rapid installation of our white stucco fence systems means no downtime between project phases and faster property sales.

For Architects & Designers

Achieve complete design freedom. We fabricate custom solutions to your exact CAD specifications, from a sleek modern stucco fence to a complex stucco and wood fence hybrid look. We provide the technical documentation you need to realize your vision without compromise.

For Commercial Properties

Elevate your brand presence with a decorative privacy fence that offers security and sophistication. Ideal for hotels, corporate campuses, and retail centers, our fences require minimal maintenance and are built to withstand high-traffic environments.

For Luxury Homeowners

Create the ultimate front yard stucco fence or backyard oasis. Our systems provide the decorative privacy fence ideas you need to build a secure, elegant, and quiet retreat that is both beautiful and easy to install.

Before and after

Discover our workHow our stucco fence elevates your business presence

A fence is more than just a boundary—it’s the first impression your clients, partners, and visitors get of your property. A well-engineered stucco fence instantly communicates professionalism, security, and style, setting your business apart before anyone even steps inside.

- Professional Image that Builds TrustA solid, monolithic stucco wall fence adds an air of permanence and prestige. It demonstrates that your company invests in quality and detail, which helps establish credibility and confidence with clients and investors alike.

- Durable and Low-Maintenance SolutionUnlike wood or metal fencing that requires constant upkeep, a stucco privacy fence is engineered to withstand harsh weather, UV rays, and time—staying beautiful year after year with minimal maintenance. This low total cost of ownership is a smart investment for any commercial property.

- Custom Design for Your Brand IdentityYour property should be an extension of your brand. With a variety of textures, finishes, and the ability to integrate custom decorative fence panels or even logos, our architectural fence systems can be tailored to align perfectly with your company's architectural style and brand image.

Voices of our clients

From your first idea to the final installation — our process is clear, fast, and designed to make every detail simple.

FAQ

- How fast is installation?

Usually about 165–190 linear feet in four workdays. On a particularly tight downtown site, an entire run was installed with just a small crew and no heavy equipment — and still finished ahead of schedule.

- Will it feel quieter next to a busy road?

Absolutely. Most people notice the difference the first evening. The shell reflects harsh noise while the foam core absorbs the rest. At a project near a Miami expressway, the change was dramatic enough that residents started using their outdoor space again.

- Can you match our façade color exactly?

Yes — we’re obsessive about that. Foam takes acrylic with precision, and we routinely achieve perfect visual matches. A historic property in Savannah once had us match an aged brick tone, and even the neighbors assumed the new wall was original masonry.

- What if we have a big grade change?

No problem. Foam follows contours far more easily than concrete or masonry. Instead of awkward steps, we can create smooth transitions that maintain visual calm and proper drainage.

- Will a white finish last in coastal weather?

It will if the system is specified correctly. With the right coating and finish, walls along the Gulf Coast have stayed chalk-free and color-true for years. Occasional rinsing is usually all the maintenance required.

- Are foam panels strong enough for high winds?

Yes. When everything is engineered thoughtfully — from precise anchor spacing to slightly shortened modules in the most exposed spots — the fence doesn’t behave like a fragile structure, but like a seasoned sailor standing firm on deck in the middle of a storm. Even hurricane-level coastal winds don’t faze it: it doesn’t shift a millimeter, doesn’t crack, and never gives in to the elements. At one property near Daytona Beach, the fence looked as if it had been installed yesterday, even after an entire storm season — perfectly straight, steady, and untouched. It’s more than just strength; it’s a quiet confidence you can feel when you look at it, as if the architecture itself is saying, “I’m right where I belong — and I’m not going anywhere.”

- Can we include a recessed logo without a billboard look?

Definitely. Because foam is so easy to shape, recessed details feel purposeful rather than forced. One Atlanta property incorporated its logo into a shadowed niche with subtle lighting — the effect is elegant by day and welcoming at night.

- Is six feet high enough for privacy?

Often, yes. Especially when paired with strategic planting. And if local codes require more, we can add height without creating a fortress-like presence.

- What do you need to provide a quote?

Length, height, a style cue, and a few photos. Include a color sample early and we can return strike-offs with the estimate — speeding approvals by up to a week.

- We want a wood look without the upkeep.

We can achieve that easily. Slim aluminum fins paired with textured foam surfaces create the warmth and light play of wood without rot, refinishing, or fading. On one residential project, the “wood” still looked fresh three seasons later with nothing more than a garden hose rinse. The result was as visually appealing as natural wood and perfectly matched the desired look of the homeowner.

Your essential design & spec catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Let's build something great together

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!

More our solutions

We provide architects, builders, and homeowners with turnkey decorative elements that transform any project — fast, easy, and cost-effective.

Blog posts

Ready-made facade elements with factory assembly. Fast installation, fewer errors, and reduced costs.

Construction companies

Developers

Standardized solutions for neighborhoods. Quick delivery, unified style, no downtime.

Architects and designers

Сustom solutions for the project: 144+ textures, any shapes,

and technical documentation.

Stucco Architectural Fencing

Architectural stucco fencing with an EPS foam core always appears as the finishing touch of a property, complementing the architecture of the main building. Such a structure doesn’t disrupt the rhythm of the design — instead, it looks clean, refined, and striking.

Our EPS foam constructions maintain their shape regardless of weather conditions — through heavy rain, intense heat, and strong winds — without losing their appearance or structural integrity. These fences can replicate the texture and character of materials like wood or stone, yet have clear advantages over them: they are lightweight, easy to install and maintain, and require no additional upkeep, unlike traditional wooden fences.

The difference between installing a stucco fence and a stone or wooden one is significant: a stucco fence can be assembled quickly and effortlessly. The joints are simple to align and conceal, resulting in a neat, elegant, and stylish look. Curves finish exactly where they should, and the surface feels pleasant to the touch. The end result is not just an ordinary fence, but a true architectural boundary — a defined space that forms its own small domain, where the rhythm of the landscape, architecture, and lighting coexist in harmony.

What It Is — Plain and Simple

Technically: EIFS.

In real life such a foam-based product offers a number of advantages. It ensures high precision and essentially serves as a multi-layered “skin” for the perimeter of any structure. The decorative layer looks aesthetically appealing and modern, yet it also performs practical functions such as sound insulation, protection, and resistance to external factors.

Every element in the fence system matters: only through their combination is it possible to create not just the exterior appearance of the object, but also its functional purpose, achieving harmony between form and utility.

What It Does — and Why Foam Makes It Better

Core

Molded EPS – Expanded Polystyrene. The foundation of the entire system — light as a feather, yet crafted with jeweler-like precision, thanks to CNC cutting technology. It can take virtually any shape while maintaining its key advantage — minimal weight. At the same time, it remains resistant to heavy loads and is completely immune to rust and rot.

Impact shell – Protective layer.

- Fast-cure urethane

- 100% acrylic + mineral aggregate

Internal stiffener

PVC Schedule 40

The hidden muscle. It holds long spans steady without the weight or mess of steel cages, giving structure without slowing the build.

Post interface

Steel + expanding resin

Base

Concrete footing

The familiar foundation beneath it all — traditional concrete that provides stability and reliability to the entire structure, while the foam above keeps the system light and easy to handle.

This is not just a list of durable materials — it’s a small ecosystem where every layer knows its role. Together, they create something that is light yet strong, precisely engineered yet graceful — a perimeter that feels like part of the architecture, not an afterthought added at the last moment.

When site access is limited and cranes can’t be used, lightweight panels weighing under 120 pounds (about 55 kg) can be easily carried by two people.

Finishes & Joints

Reveals must read as a continuous line across joints, even in raking light.

Panel seams should step no more than 0.07 in.; surface variation stays within 0.07 in. over an 8 ft span.

Color accuracy holds within tight tolerances under both daylight and warm light.

Edges stay smooth and transitions stay clean.

Privacy With Poise — Calm Without the Bunker Feel

People aren’t asking for fortresses anymore. They want space that breathes — a sense of calm, not defense.

Entrances feel intuitive. Light and signage start to cooperate. Even night scenes look better — leaner, more intentional — because the surfaces carry the light instead of scattering it.

You can feel the shift before you name it. People lower their voices again.

One hotel proved it perfectly. Posts se t on a Wednesday, panels lo cked in by Friday, gu ests ch ecking in by sunset.

The manager said visitors kept asking about “the stone wall” — where they could get one.

That’s when you realize: design isn’t decoration. It’s doing work.

Design That Lands — Curves, Shadows, Niches Without Heavy Machinery

Curves follow their intended paths. Shadows fall where the plans predicted. Niches hold branding with understated elegance during the day and glow gently at night. Heavy materials resist those design gestures; foam makes them simple.

Front yards stay open and welcoming while still framed. Copings trace radii smoothly. Service cutouts disappear into the background. In one coastal marina, carefully shaped modules with hidden conduit and a warm, narrow light wash created a walkway that felt tranquil and deliberate — guests now photograph the view instead of the infrastructure.

Quieter by Design

These fences are tuned for the way people actually use spaces. The urethane shell reflects harsh high frequencies, while the foam core absorbs the rest. That subtle engineering makes speech easier to hear and conversations more natural.

Design Selections That Make Sense

Fencing that harmoniously integrates with the greenery along the perimeter of any architectural site.

Six-foot decorative panels that provide privacy and comfort while allowing air and light to flow freely, without feeling heavy or obstructive.

Finishes and textures that resemble wood, stone, or brick — authentic in appearance, yet easy to install and maintain.

Architectural accents that can suit both traditional and modern styles, without requiring any changes to the underlying structure.

Predictable Process and Simple Maintenance

Installation process:

- Layout and pour the footing.

- Set posts perfectly plumb (with metal lath).

- Confirm diagonals — no racking means no surprises.

- Drop prefabricated panels into place with a clean, dry fit.

- Lock foam to steel with expanding resin.

- Seal, tone, and set the lighting.

Crews regularly achieve 165–190 linear feet of installation in four days. Cranes are rarely needed — the structure is that lightweight. One downtown project even completed an alley run in less than three days with nothing more than pallet deliveries and a small crew.

Dollars, Days, and Risk — Where Foam Keeps Paying Off

Foam drives savings that reach far past the price tag.

Lighter panels mean fewer hands on site.

Where Partnership Actually Feels Like Partnership

- Built in the USA with precision you can trust.

- Custom is standard — send a color code, ge t a perfect match.

- Finishes that look like natural materials without their maintenance issues.

- Documentation that makes decisions faster.

Delivery happens on the site’s terms, not the other way around. We plan around real-world conditions — traffic windows, tight access, staging limits — so materials arrive when and how they’re needed. No surprise delays, no pallets sitting in the rain, no work grinding to a halt because something showed up too soon or too late.

Precision is baked in from the start, so installation feels more like assembly than construction. Panels slip into place without resistance, tolerances stay tight without constant adjustments, and punch lists shrink down to almost nothing — leaving the final walk-through feeling more like a celebration than a correction session.

We don’t compromise on two things: perfectly plumb posts and accurate color matching. Get those right and everything else falls into place.

Ready When You Are

Send us the length, height, a style cue, and a few photos. We’ll provide an estimate, physical samples, and a 3D preview. If you’re still designing, even better — we’ll prototype profiles and textures early so the build unfolds without drama.

Ready to Get Started?

Ready to bring your project to life? Request a quote today — it’s the fastest way to move from idea to reality. Send us your project details, and within just a few days you’ll receive a tailored design concept, a detailed cost estimate, and physical samples you can hold in your hands.

Whether you’re still sketching early concepts or finalizing specifications, our team will be there to guide you from the first brief all the way to installation — making sure every line, color, and detail lands exactly as you imagined.

Your essential design & spec catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Let's build something great together

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!