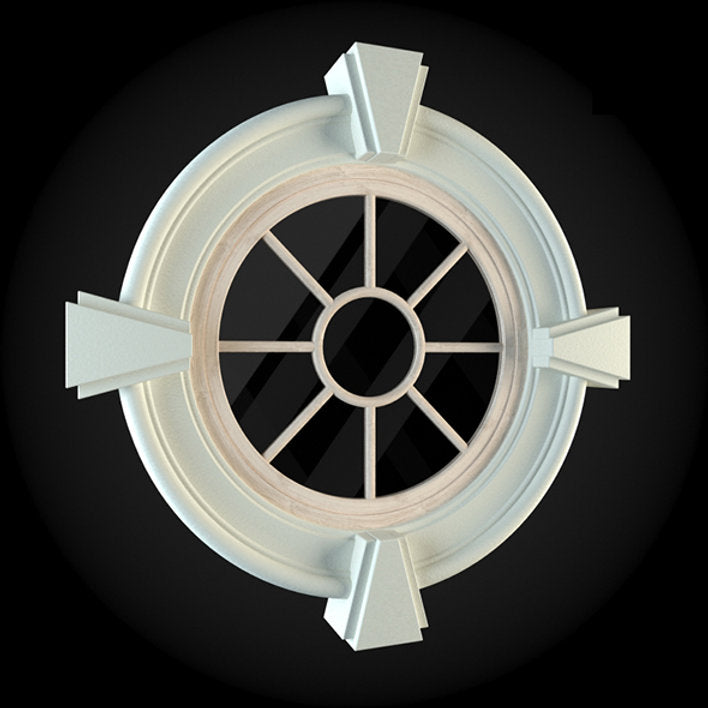

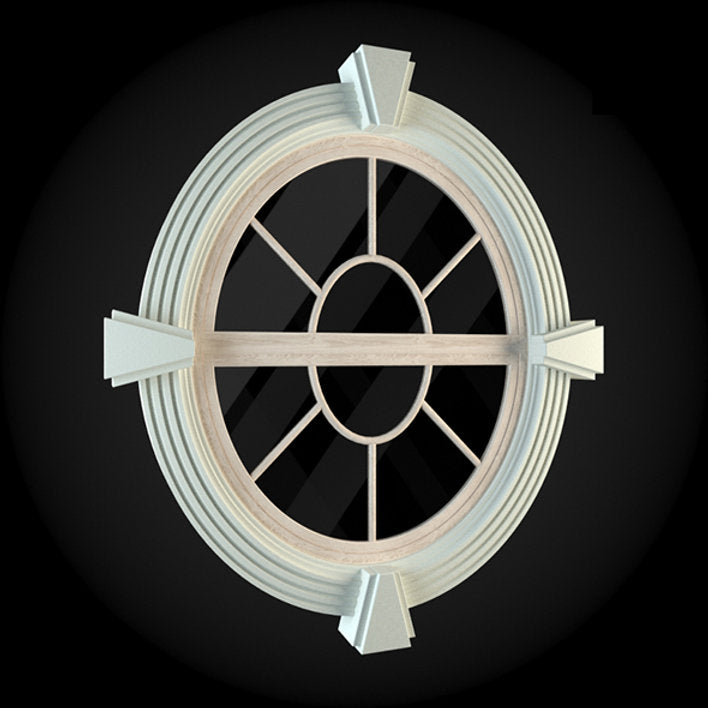

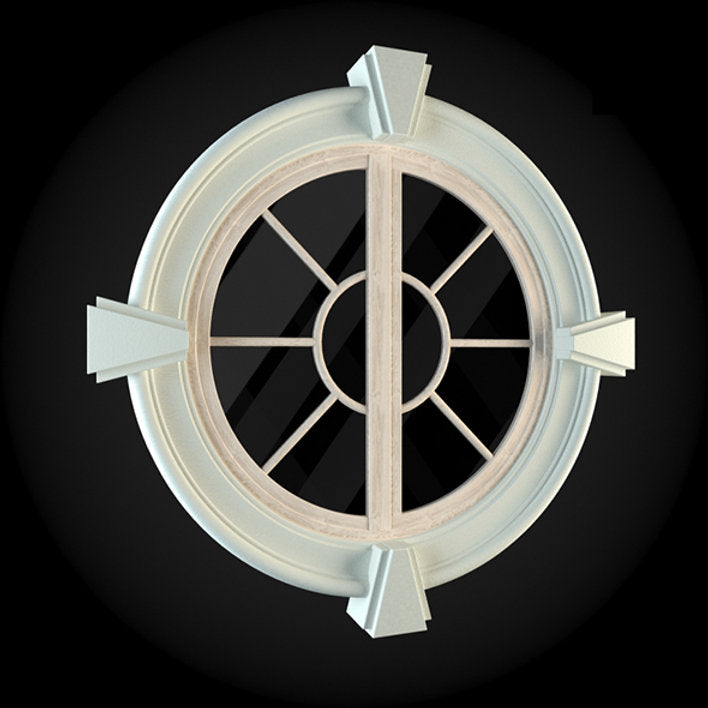

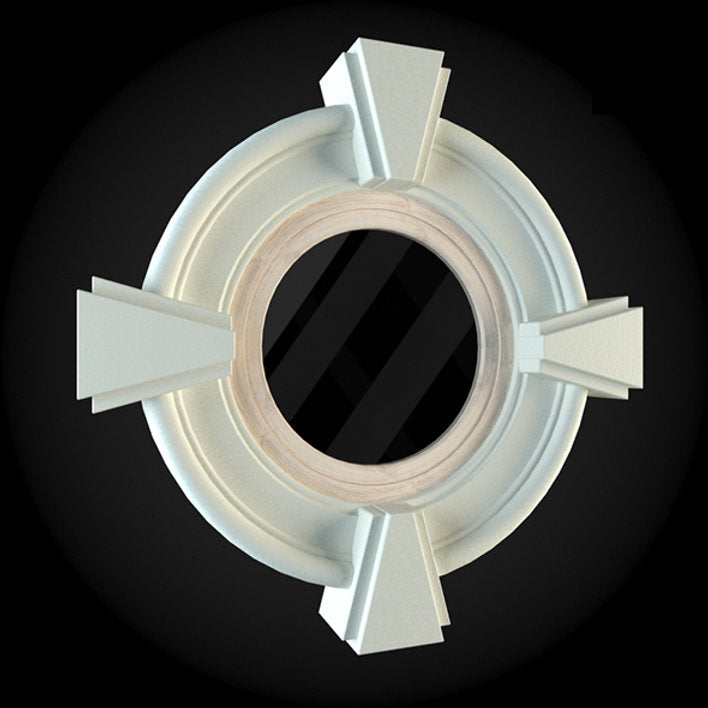

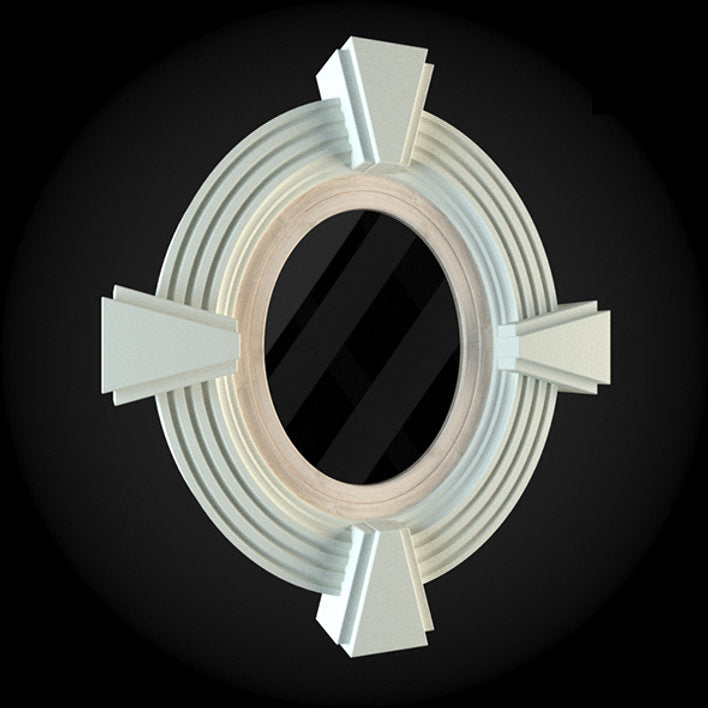

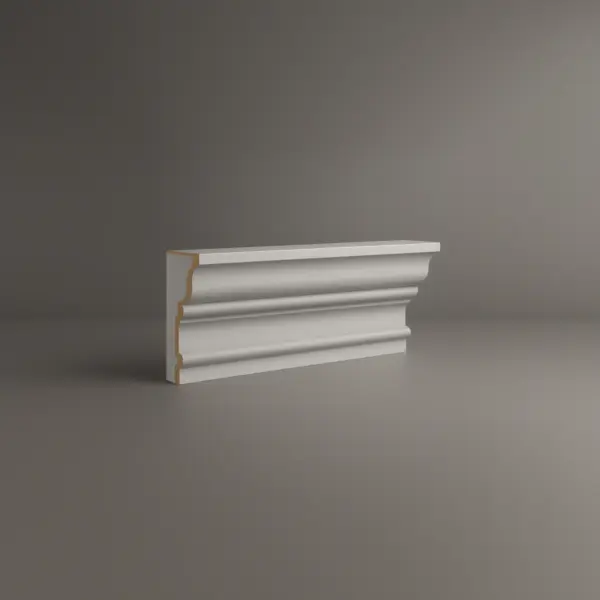

| Width | 45, 48 |

|---|---|

| Height | 80, 90 |

| Depth | 12, 15 |

| color | |

| Endcaps | 2-sided, 3-sided |

Options Sides |

2-sided, 3-sided, 4-sided |

| Texture | Stone, Wood |

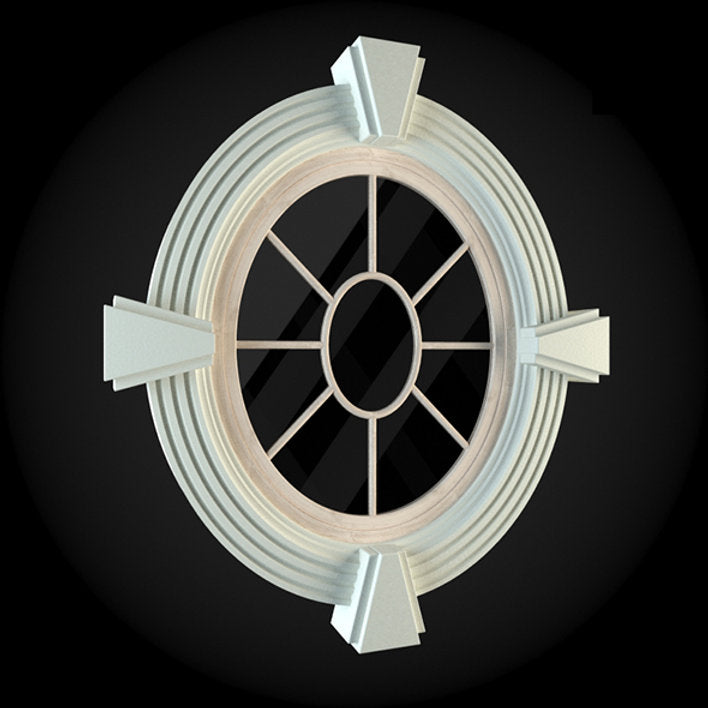

Window Surround 001

fgdfgdfgdfgdfgdfg3423423ydrtdrtrt

fgdfgdfgdfgdfgdfg3423423

fgdfgdfgdfgdfgdfg

Our project gallery

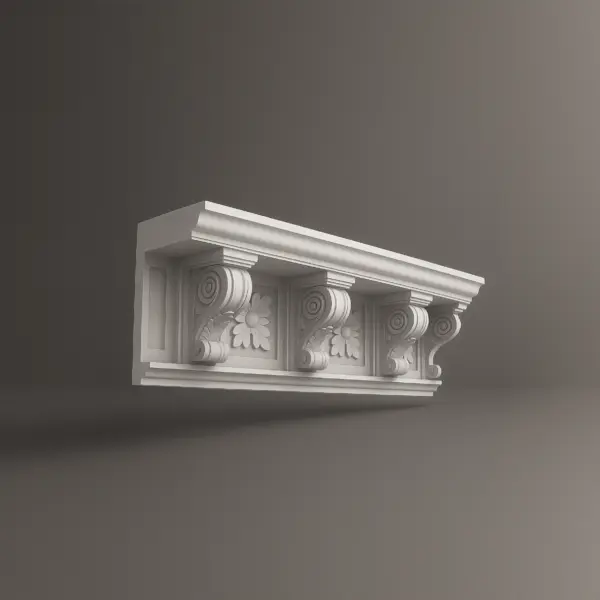

Similar products

Architectural Shapes — your trusted partner

We create custom decorative shapes for architects, builders, developers, hotels, and homeowners — delivering elegant, durable, and easy-to-install solutions across the USA.

Expert craftsmanship, design precision

Our team draws from decades of experience in classical and modern architecture, ensuring each column delivers both visual elegance and structural reliability.

Lightweight yet strong materials

Unlike traditional stone, our EPS-based columns are reinforced and coated for strength. They’re easy to install, highly durable, and weather-resistant — perfect for any U.S. climate.

Fully customizable options

From proportions and fluting to base and capital details, every element can be tailored to match your project’s style and scale.

Voices of our clients

From your first idea to the final installation — our process is clear, fast, and designed to make every detail simple.

FAQ

- Will anyone be able to tell it’s foam?

No. Inspectors in Tampa once tapped the surrounds convinced they were stone — they weren’t.

- How do they hold up near the ocean?

Exceptionally well. With UV- and salt-resistant coatings, installations on the Miami waterfront are still going strong after eight years.

- How long do they last?

Decades. We have external window surrounds in Atlanta that have been performing perfectly for over 20 years.

- Is installation really that much faster?

Yes. Most residential installs finish in 1–2 days. Commercial projects vary but are always faster than stone or precast.

- Can surrounds act as mini sunshades?

Acting as more than just a design element, profiles with 1.5–2 inches of projection create real shading and improve thermal performance — a subtle but valuable benefit in sunny climates.

- What is the typical cost of your window surrounds?

The cost of our window surrounds varies based on size, profile complexity, and finish. However, due to significantly lower labor, equipment, and logistics expenses, the total installed cost is consistently lower than traditional precast concrete or carved stone. Contact us with your project specs for a custom quote.

- How are these exterior window surrounds installed?

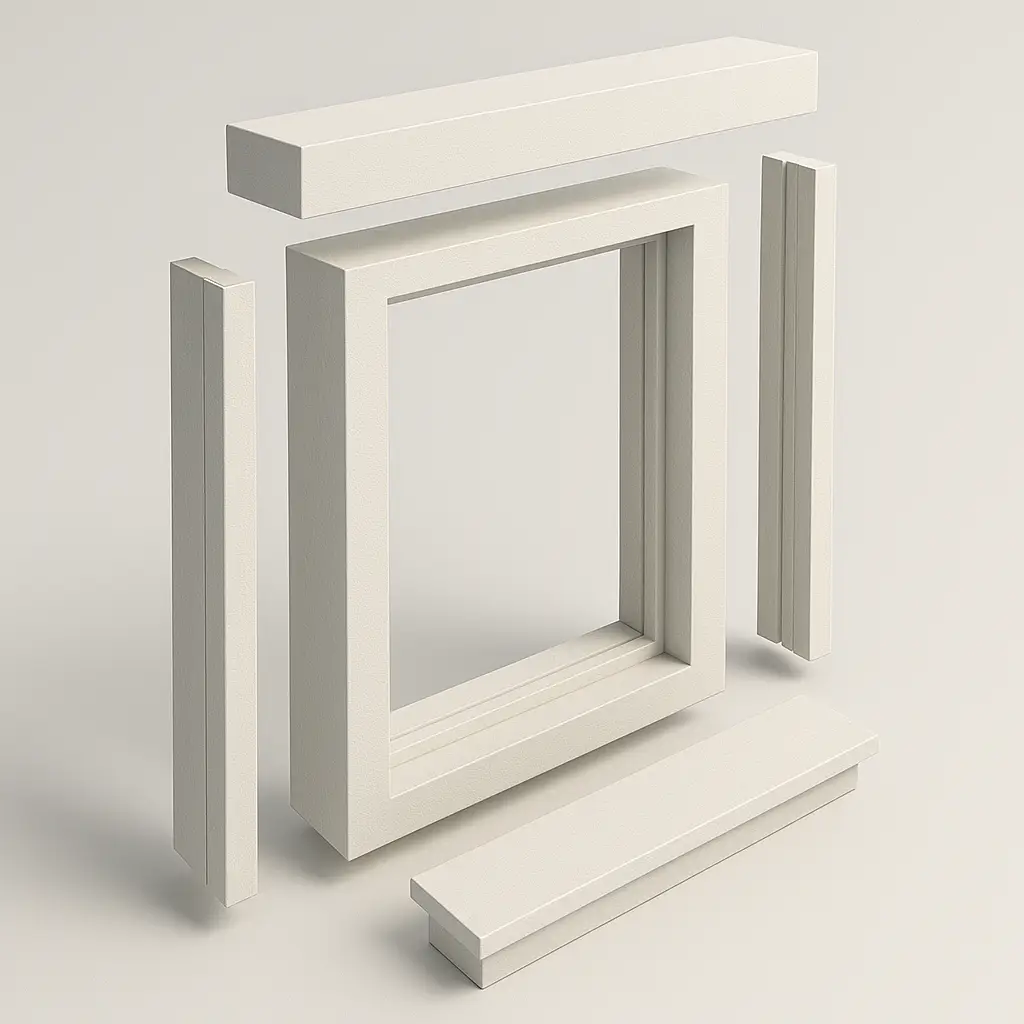

Our system is designed for efficiency. The prefabricated, lightweight **window surround** pieces are mechanically fastened and/or attached with construction adhesive to the building substrate. The process is fast, simple, and can be handled by a small crew without heavy machinery.

Your essential design & spec catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Let's build something great together

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!

More our solutions

We provide architects, builders, and homeowners with turnkey decorative elements that transform any project — fast, easy, and cost-effective.

Blog posts

Ready-made facade elements with factory assembly. Fast installation, fewer errors, and reduced costs.

Construction companies

Developers

Standardized solutions for neighborhoods. Quick delivery, unified style, no downtime.

Architects and designers

Сustom solutions for the project: 144+ textures, any shapes,

and technical documentation.

Window surrounds

In architecture, details often play a crucial role

A missed deadline, a design mismatch, or an installation budget overrun can significantly impact a project’s profitability and the client’s satisfaction. Window surrounds may seem like a small detail compared to an HVAC system or a steel frame, but in reality, they solve tasks that go far beyond decoration. The appearance of a building — its architectural style and overall character — is shaped precisely through such subtle elements. They not only protect the structure and simplify installation but also make the building more visually appealing. Projects gain identity and atmosphere thanks to these architectural details.

For more than two decades, we’ve seen the same situation many times: a client chooses window surrounds that look like stone but are more affordable, lightweight, and meet the required technical specifications. Foam materials are an excellent solution that meets all these criteria. First of all, because they are practically indistinguishable from stone, concrete, or marble. They can replicate nearly any texture or surface finish while being far more cost-effective in production, installation, and logistics. Their properties allow us to offer a 20-year warranty, as these products retain their performance characteristics for many years.

This is precisely what makes foam-based architectural elements a popular choice today among architects, designers, developers, contractors, and other clients who value not only decoration but also aesthetics and cost-efficiency.

The real value of window surrounds in modern projects

Window surrounds aren’t just about appearance — they’re a strategic decision with real consequences for schedule, budget, and property value. They impact how a building performs, how it’s perceived, and how profitable it becomes. Here’s why they matter so much:

- Cohesive design: Surrounds visually organize the facade, bringing balance, proportion, and intention to the home’s exterior — a subtle but powerful improvement in curb appeal.

- Moisture and UV protection.

- Brand perception and visual appeal.

- Ease of installation.

On one retail project in Tampa, for example, the developer initially specified cast stone surrounds. By switching to foam, the installation was completed three weeks ahead of schedule, and the total exterior package cost dropped by 14%. That’s not a marketing claim — that’s what happens when design, engineering, and construction align with practical realities.

From Renaissance stonework to digital fabrication

The story of external window surrounds is deeply intertwined with the story of architecture itself. In ancient Rome, deep window moldings weren’t just aesthetic choices — they served a functional purpose, casting shadows that cooled interior spaces. During the Renaissance, surrounds evolved into expressions of artistry and status: elaborate keystones, scrollwork, and layered profiles became signatures of wealth and craftsmanship.

By the 20th century, as modernism embraced minimalism, external window surrounds became simpler but no less significant. The stepped trims of Miami’s Art Deco facades, for example, added rhythm and depth to otherwise flat surfaces. In the 1980s and ’90s, synthetic materials — lighter, easier to shape, and more versatile — entered mainstream construction through EIFS systems.

Today, digital fabrication and precision coatings allow us to replicate centuries-old designs or invent entirely new ones with millimetric accuracy. Want modern faux stone window surrounds that look like weathered limestone but install in two days? That’s standard practice now. Even something as subtle as a 1.5-inch shadow line around a window can change how a building is perceived — our brains associate depth with craftsmanship and quality. That’s why even minimalist designs often rely on simple decorative window surrounds to complete the look.

Why foam is the smartest choice — and how we engineer it

We work exclusively with foam — and in our view, that’s one of the best decisions we’ve ever made. It’s not about trends or shortcuts; it’s the result of decades of testing, problem-solving, and lessons learned on real job sites. Over and over again, foam has proven itself superior to stone, concrete, and wood where it matters most: strength without unnecessary weight, creative freedom without runaway costs, and consistency without the headaches that used to keep project managers awake at night.

Core and density

We use high-stability EPS (typically 1.5–2.0 lb/ft³), which ensures precise geometry during CNC cutting. Because foam is so light, it barely adds any load to the structure — think of it as dressing the building instead of weighing it down. That reduced weight drastically cuts the demand on the structural framework and anchoring system, which isn’t just convenient but critical in retrofit projects or mid-rise commercial builds, where every extra pound affects budgets and safety margins.

Protective coatings

Each profile is coated with a next-generation, fire-rated polyurea hard coat. This creates a tough, impact-resistant shell that shrugs off weather, UV, and mechanical stress. In coastal zones like Miami, an application of concrete sealer topcoat protects against harsh marine environments and maintains performance for decades.

Custom textures and finishes

Foam is a true chameleon. It can be shaped and finished to mimic nearly any material:

- Stone: Porous, chiseled, and weathered — visually identical to limestone or travertine.

- Concrete: Smooth, pitted, and industrial — replicating the raw aesthetic of poured cement or precast blocks.

- Wood: Grainy, knotted, and rough-hewn — indistinguishable from heavy timber or reclaimed barn wood.

Foam vs traditional materials

Foam isn’t just more efficient — it outperforms traditional materials in almost every category:

| Parameter | Foam (reinforced) | Cast stone | Precast concrete | Wood |

|---|---|---|---|---|

| Weight | Ultra-light | Heavy | Very heavy | Medium |

| Structural load | Minimal | Significant | High | Moderate |

| Installation | Manual, no machinery | Cranes required | Heavy equipment required | Manual, weather-sensitive |

| Design flexibility | Unlimited | Limited by mold cost | Limited | Limited by stability |

| Coastal performance | Excellent with proper coating | Prone to salt damage | Rebar corrosion risk | Warps and swells |

| Cracking risk | Very low | Hairline cracks common | Shrinkage cracks | Expansion-related cracks |

| Maintenance | Optional repainting | Joint repointing | Costly repairs | Frequent sealing/painting |

| TCO (10 yrs) | Predictable, low | Medium-high | High | Unpredictable |

Foam’s benefits extend far beyond the initial cost. With fewer trades involved, fewer delays, and almost no callbacks, it offers predictable long-term performance. One contractor in Savannah told us that switching to foam window surrounds cut their punch list time in half — nothing needed grinding, cutting, or retrofitting on site.

Where and how window surrounds make an impact

Classical architecture — without the weight: We replicated traditional Tuscan-style surrounds for a villa in Winter Park, complete with keystones and cornices. The entire facade was installed by a three-person crew in under 48 hours — impossible with stone.

Minimalist commercial projects: In Atlanta, a corporate office used linear external window surrounds to break up large glass expanses. The result was a clean, balanced rhythm and a building that appeared far more expensive than it was.

Hospitality and retail: Brand experience starts at the facade. In Tampa, a retail plaza needed an upscale look on a tight timeline. Foam surrounds with a metallic finish were installed in days, and leasing inquiries doubled within a month.

Logistics and installation — speed without compromise

Foam’s low weight turns installation from heavy construction into a finishing trade.

- No cranes or lifts required.

- Sections arrive labeled with drawings and assembly guides.

- Small crews can complete a building in days, not weeks.

On a 10,000 sq. ft. office project in Jacksonville, decorative window surrounds eliminated the need for a crane entirely — saving the general contractor $22,000 in equipment costs.

Long-term ROI and total cost of ownership

For decision-makers, cost is about more than material price — it’s about total cost of ownership. Foam lowers costs across the board:

- Shipping: Lighter loads reduce transport costs.

- Labor: Faster installation requires less specialized labor.

- Maintenance: No spalling, joint failures, or frequent repainting.

- Performance: Improved thermal stability reduces expansion and contraction issues.

For integrators and resellers, exterior window surrounds expand your product range and margin potential without increasing inventory complexity.

Why working with us just makes sense

We don’t just supply materials — we deliver engineered solutions that eliminate risk and add value.

- Made in the USA — faster lead times and predictable logistics.

- Full design support — from concept to CAD to shop drawings.

- Custom colors and finishes matched to your materials.

- 3D mockups and samples available before production.

- Guaranteed precision and specification compliance.

And yes, we’re genuinely passionate about what we do. Few things are as satisfying as watching a plain wall transform into an elegant, high-performance facade with the right window surrounds.

Your essential design & spec catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Let's build something great together

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!