About our architectural molding systems

A complete toolkit of lightweight profiles, engineered to bring architectural character to any surface.

Built to define and transform any space

Our decorative molding isn’t just trim; it’s an architectural tool. Crafted from a high-density, lightweight composite core, our moldings empower you to add character, create rhythm, and build visual hierarchy in any environment. From grand, sweeping curves in a corporate atrium to crisp, modern decorative wall molding panels in a boutique hotel, our system is engineered for flawless execution.

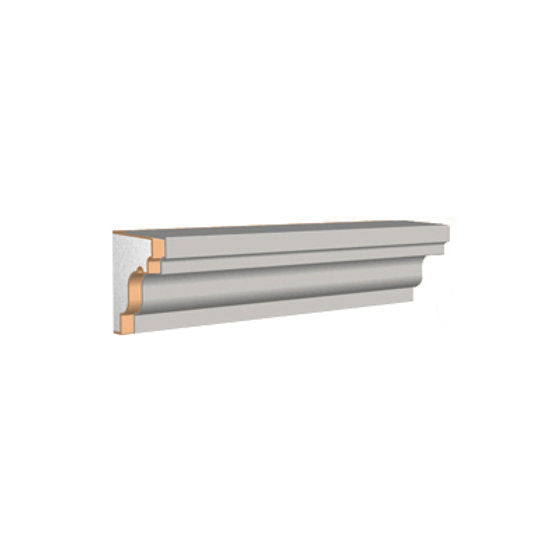

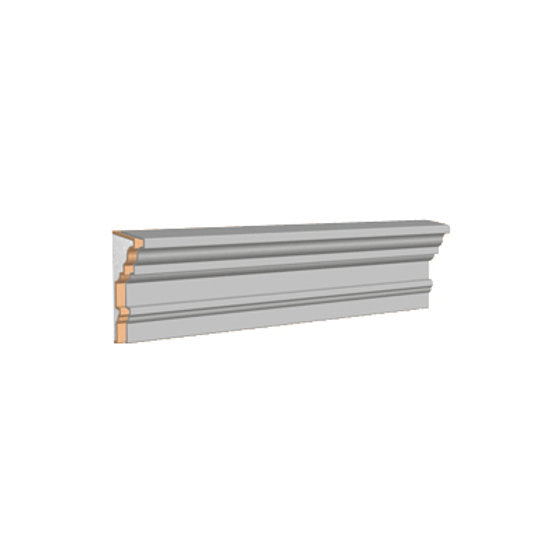

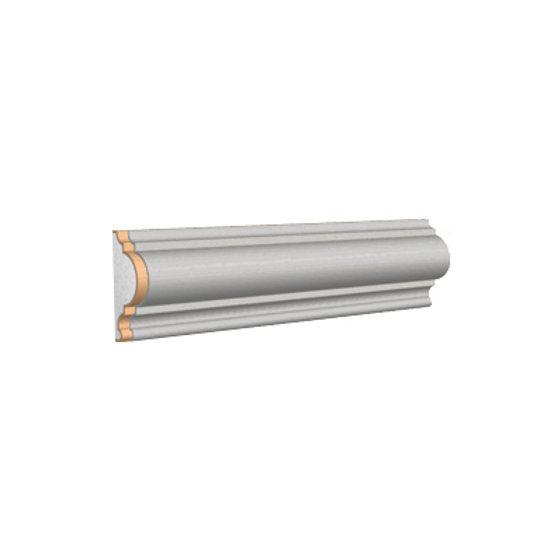

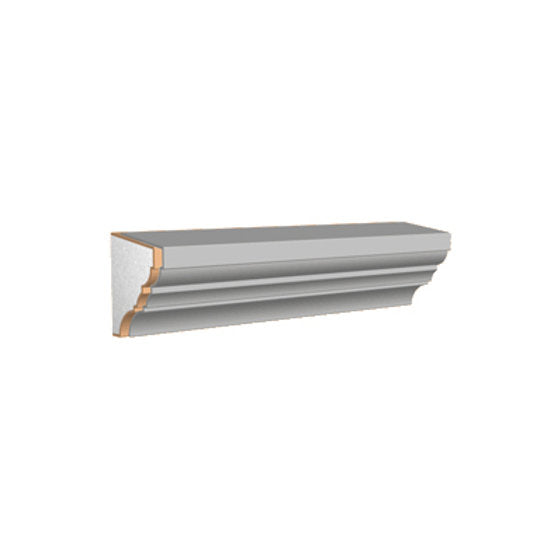

Each element is precision-made to serve a distinct architectural purpose:

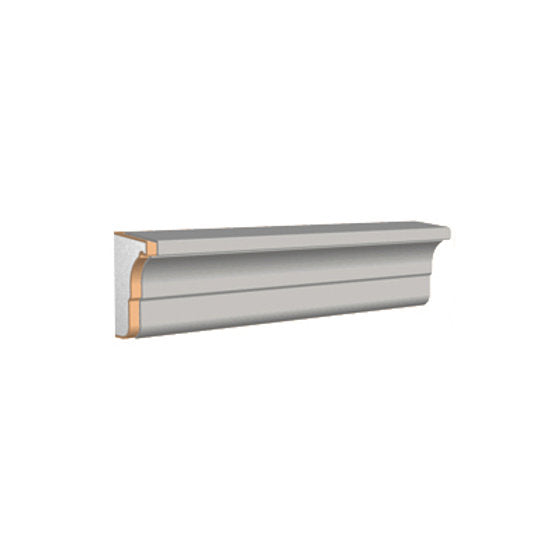

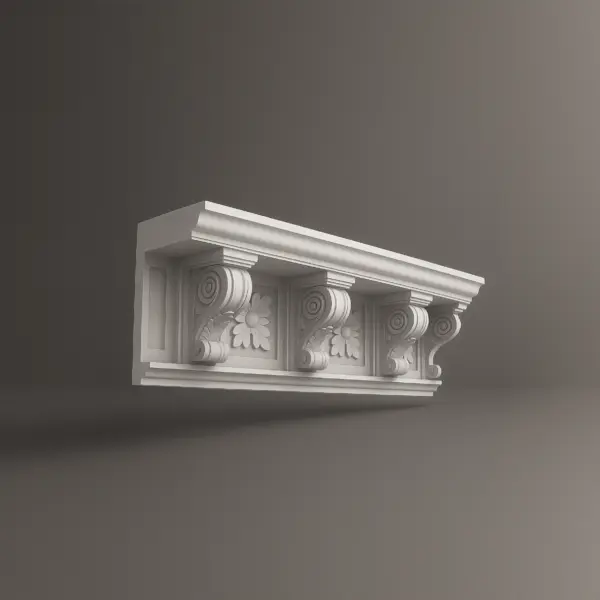

- Crown Molding: To draw the eye upward and add a finishing touch of elegance where wall meets ceiling.

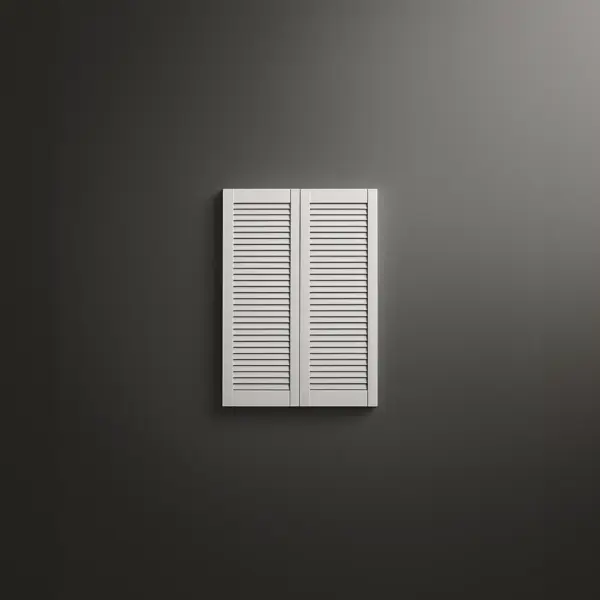

- Wall Molding & Paneling: To turn flat, boring walls into dynamic surfaces with depth and character.

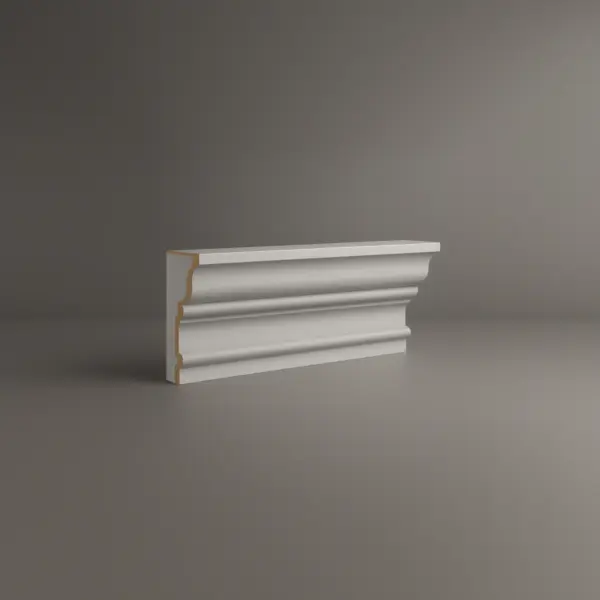

- Casings & Surrounds: To frame windows and doors, transforming simple openings into stately features.

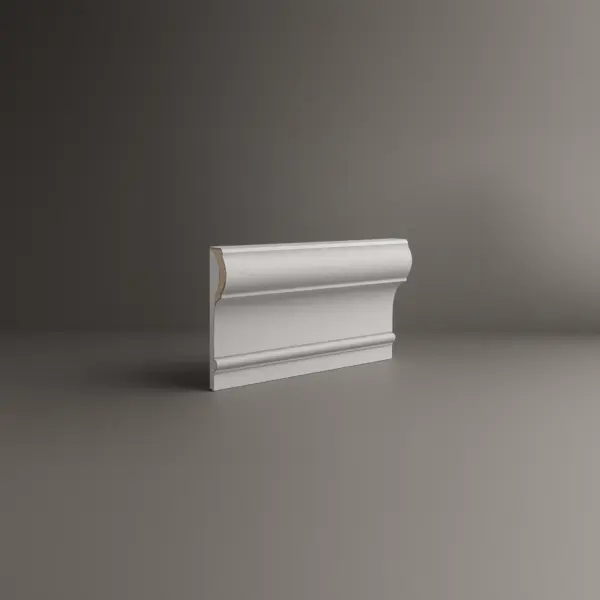

- Baseboards & Chair Rails: To ground the room and provide a durable, aesthetic transition.

Get a modular system that installs with the clean precision your design deserves.

The science behind flawless form and fierce durability

Our architectural moldings interior and exterior systems are born from an advanced material science that leaves traditional methods behind. It starts with a structural, high-density Expanded Polystyrene (EPS) foam core, precision-cut by CNC routers to match your exact CAD files. Every curve, every edge, every detail is perfect from the start.

But the real magic is the armor. We encapsulate this lightweight core in our signature polyurea hard coat. This spray-applied elastomer creates a seamless, impact-resistant, and completely waterproof shell. This isn’t just foam anymore; it’s a monolithic composite with incredible strength that laughs at dents, moisture, and time.

The final surface is a smooth, paint-ready finish that provides the perfect canvas for your color palette. This advanced construction ensures your decorative molding is not only beautiful on day one but stays that way for decades.

Assortment of decorative moldings

EPS foam molding vs. traditional materials:

The unfair advantage

Ready to Experience the Difference?

Stop fighting with heavy, fragile, and outdated materials. Choose a lightweight, indestructible, and fully custom decorative wall molding solution. Built to last, made in the USA.

Let's talk about your project!

Discuss my projectExtremely Heavy

Requires costly structural reinforcement, specialized framing, and engineering.

Slow, Messy & Costly

Requires expensive, specialized crews and takes weeks, inviting project delays.

Fragile & High-Maintenance

Prone to cracking, chipping, and rot. Requires constant, costly repairs and upkeep.

Limited & Expensive

Custom work is prohibitively costly. Your best ideas often get value-engineered out.

High Upfront & Hidden Costs

Massive labor and material costs are compounded by engineering and inevitable long-term repairs.

Ultra-Lightweight

Mounts directly to any surface. No structural engineering or reinforcement needed.

Rapid, Clean Installation

A small crew installs in hours, slashing labor costs. No mess, no specialized skills required.

Indestructible & Zero-Maintenance

Waterproof shell won't crack, chip, or rot. Built to last for decades in any climate.

Unlimited Design Freedom

If you can design it, we can create it. Complex curves and custom profiles are easy and affordable.

Lower Total Cost

Drastically reduced labor, shipping, and equipment costs plus zero maintenance. A smarter long-term investment.

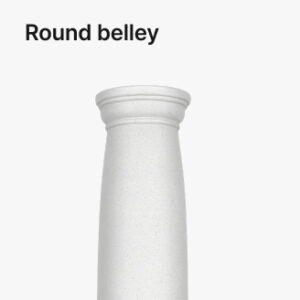

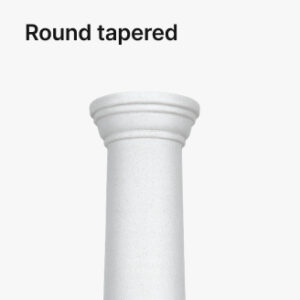

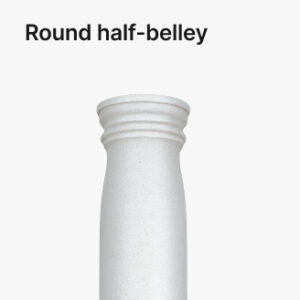

Сustom decorative moldings

How to order architectural moldings

From your initial CAD file or rough sketch to job site delivery—our process is engineered for speed, accuracy, and collaboration.

It all begins with a deep dive into your project. We work as your technical partner to translate creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your decorative architectural shapes with flawless precision, matching your approved 3D model to the millimeter.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exacting standards for form, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build custom shipping crates for your elements, ensuring they arrive on-site in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

It all begins with a deep dive into your project. We work as your technical partner to translate creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your decorative architectural shapes with flawless precision, matching your approved 3D model to the millimeter.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exacting standards for form, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build custom shipping crates for your elements, ensuring they arrive on-site in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

Our project gallery

Engineered solutions for visionary projects

Whether you’re restoring a landmark or building a new one, our system is engineered for your success

For Architects & Designers

Finally, achieve the details you’ve always envisioned. We fabricate custom profiles to your exact CAD specifications, enabling multi-layered cornices, grand ceiling details, and dramatic decorative wall molding panels without the weight and budget constraints of the past.

For Developers & Builders

Add a high-end finish that dramatically increases property value and appeal, without killing your timeline. Our lightweight moldings install incredibly fast, helping you complete projects ahead of schedule and under budget.

For Commercial & Hospitality

Create unforgettable brand environments. From the grand entrance of a hotel to the sophisticated interior of a luxury retailer, our durable moldings withstand high-traffic use and require zero maintenance.

For Historic Restoration

Replicate ornate, historical profiles with 100% accuracy but without stressing the original structure. Our system is the perfect solution for restoring architectural heritage with modern, long-lasting materials.

Before and after:

From bland box to architectural statement

Discover our workHow moldings communicate quality

Architectural details are the language of quality. They speak before you do. A well-designed molding system tells clients, guests, and tenants that you invest in excellence and permanence. It’s the difference between a space and an experience.

- An Image of Permanence and PrestigeCrisp, multi-layered moldings create a sense of solidity and craftsmanship. It’s a visual cue that signals stability and attention to detail, building trust and confidence in your brand or property from the first glance.

- Engineered for Zero HeadachesUnlike wood that splits or plaster that cracks, our composite decorative molding is engineered to be inert. It will look as perfect in year twenty as it did on day one, with nothing more than a simple wipe-down. This is a true "set it and forget it" investment.

- A Signature Look for Your BrandYour space should be an extension of your brand. We can create custom profiles that are unique to your project, allowing you to build a signature architectural identity that sets you apart from the competition.

Voices of our clients

From your first idea to the final installation — our process is clear, fast, and designed to make every detail simple.

FAQ

- How fast is installation?

Usually about 165–190 linear feet in four workdays. On a particularly tight downtown site, an entire run was installed with just a small crew and no heavy equipment — and still finished ahead of schedule.

- Will it feel quieter next to a busy road?

Absolutely. Most people notice the difference the first evening. The shell reflects harsh noise while the foam core absorbs the rest. At a project near a Miami expressway, the change was dramatic enough that residents started using their outdoor space again.

- Can you match our façade color exactly?

Yes — we’re obsessive about that. Foam takes acrylic with precision, and we routinely achieve perfect visual matches. A historic property in Savannah once had us match an aged brick tone, and even the neighbors assumed the new wall was original masonry.

- What if we have a big grade change?

No problem. Foam follows contours far more easily than concrete or masonry. Instead of awkward steps, we can create smooth transitions that maintain visual calm and proper drainage.

- Will a white finish last in coastal weather?

It will if the system is specified correctly. With the right coating and finish, walls along the Gulf Coast have stayed chalk-free and color-true for years. Occasional rinsing is usually all the maintenance required.

- Are foam panels strong enough for high winds?

Yes. When everything is engineered thoughtfully — from precise anchor spacing to slightly shortened modules in the most exposed spots — the fence doesn’t behave like a fragile structure, but like a seasoned sailor standing firm on deck in the middle of a storm. Even hurricane-level coastal winds don’t faze it: it doesn’t shift a millimeter, doesn’t crack, and never gives in to the elements. At one property near Daytona Beach, the fence looked as if it had been installed yesterday, even after an entire storm season — perfectly straight, steady, and untouched. It’s more than just strength; it’s a quiet confidence you can feel when you look at it, as if the architecture itself is saying, “I’m right where I belong — and I’m not going anywhere.”

- Can we include a recessed logo without a billboard look?

Definitely. Because foam is so easy to shape, recessed details feel purposeful rather than forced. One Atlanta property incorporated its logo into a shadowed niche with subtle lighting — the effect is elegant by day and welcoming at night.

- Is six feet high enough for privacy?

Often, yes. Especially when paired with strategic planting. And if local codes require more, we can add height without creating a fortress-like presence.

- What do you need to provide a quote?

Length, height, a style cue, and a few photos. Include a color sample early and we can return strike-offs with the estimate — speeding approvals by up to a week.

- We want a wood look without the upkeep.

We can achieve that easily. Slim aluminum fins paired with textured foam surfaces create the warmth and light play of wood without rot, refinishing, or fading. On one residential project, the “wood” still looked fresh three seasons later with nothing more than a garden hose rinse. The result was as visually appealing as natural wood and perfectly matched the desired look of the homeowner.

Your essential design & spec catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Let's build something great together

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!

More our solutions

We provide architects, builders, and homeowners with turnkey decorative elements that transform any project — fast, easy, and cost-effective.

Blog posts

Ready-made facade elements with factory assembly. Fast installation, fewer errors, and reduced costs.

Construction companies

Developers

Standardized solutions for neighborhoods. Quick delivery, unified style, no downtime.

Architects and designers

Сustom solutions for the project: 144+ textures, any shapes,

and technical documentation.

Your essential design & spec catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Let's build something great together

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!