About our architectural arch & keystone systems

We deliver the monumental look of solid stone in a precision-engineered system that assembles flawlessly on site.

The anatomy of a perfect first impression

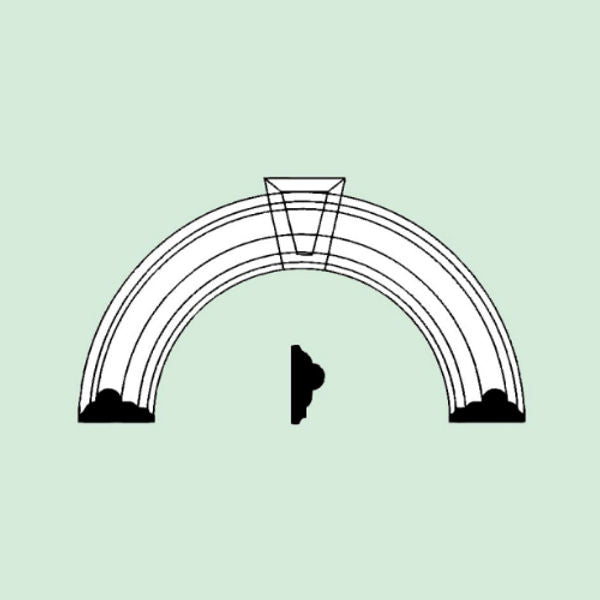

Monumental, elegant, and engineered for perfection—our architectural arches are crafted from high-density, lightweight materials to replicate a solid, monolithic stone archway without the engineering nightmare. Perfect for creating powerful first impressions on commercial properties and luxury homes, these systems add a definitive statement of quality and design authority.

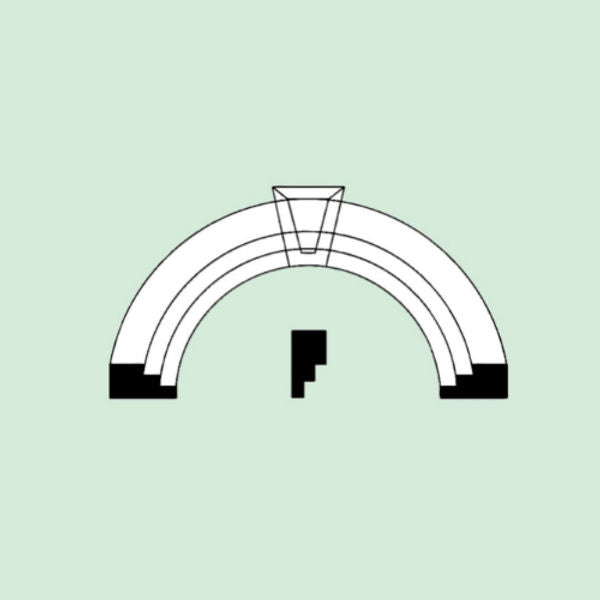

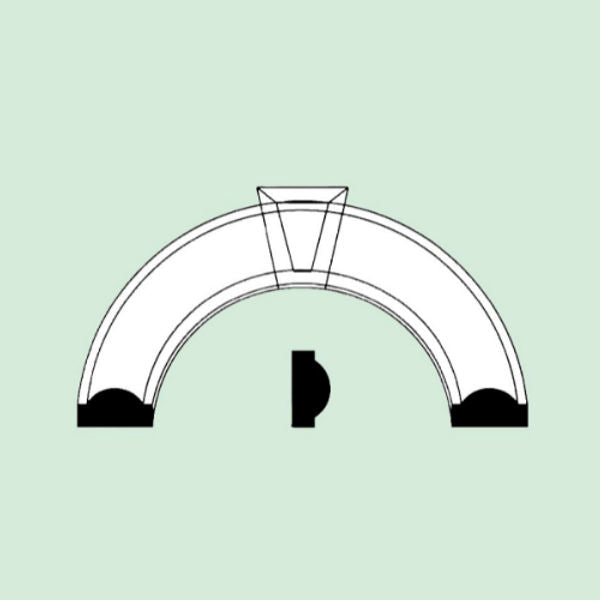

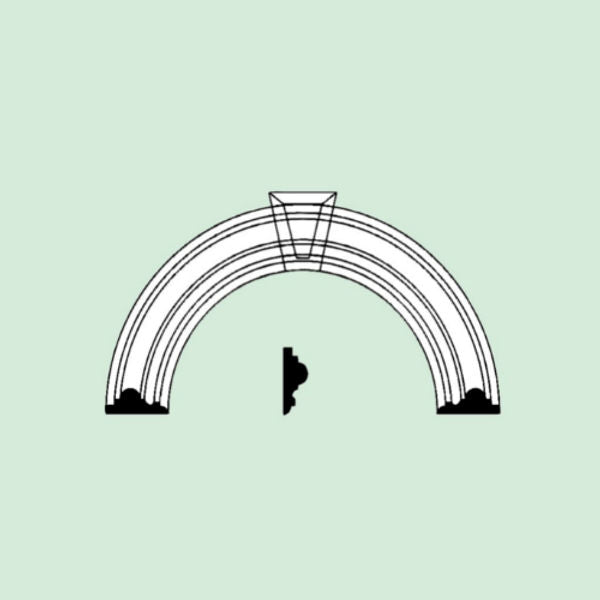

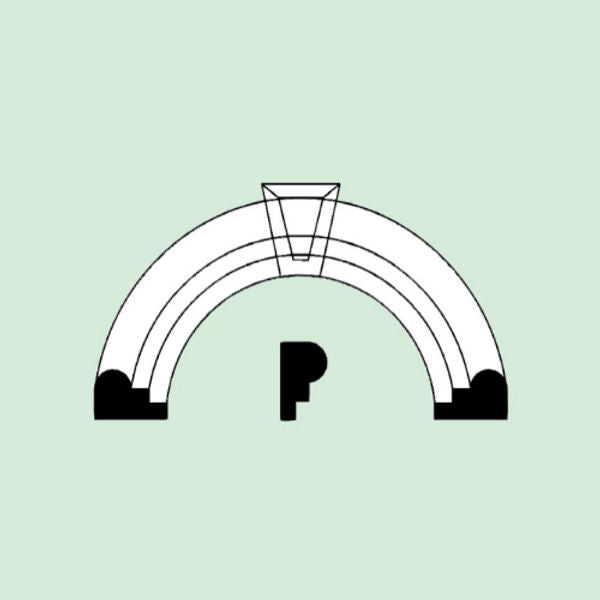

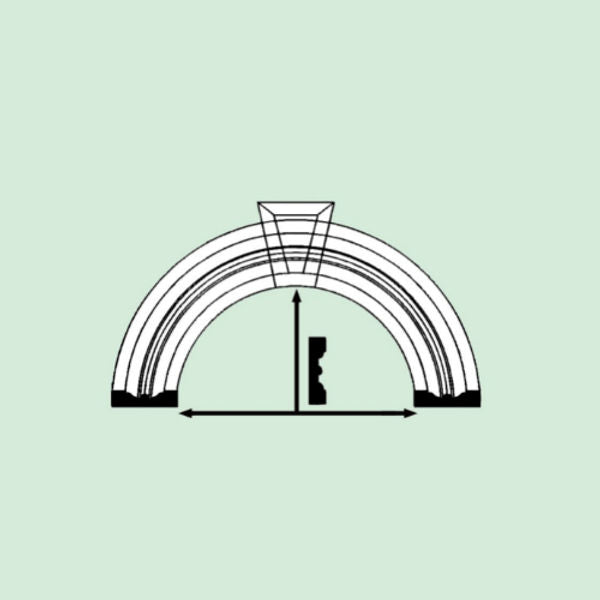

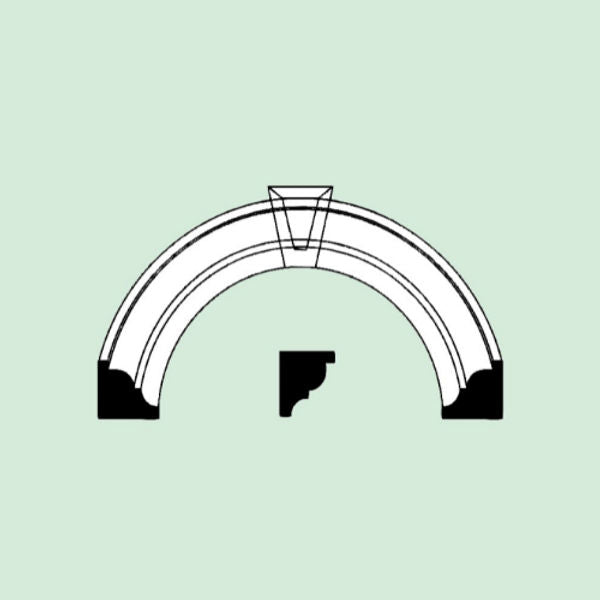

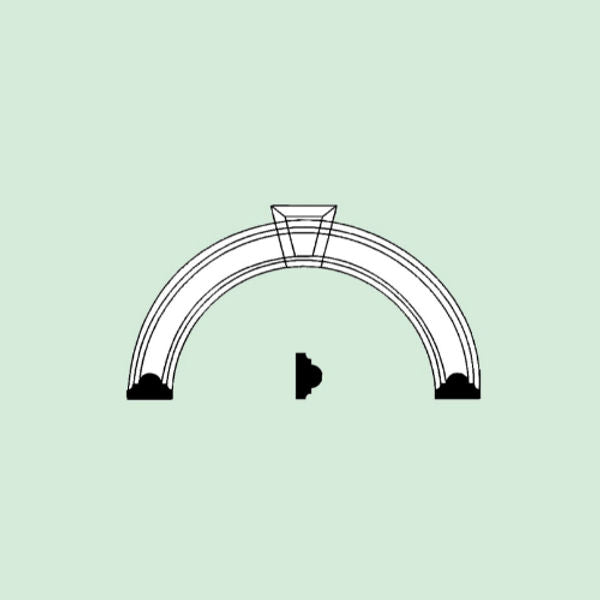

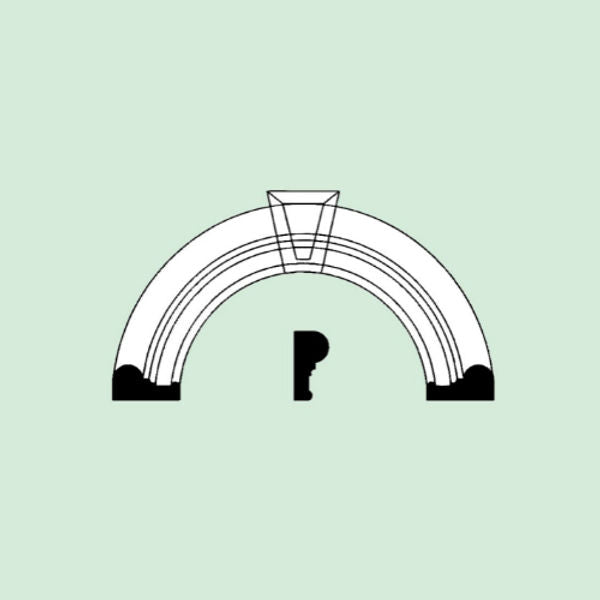

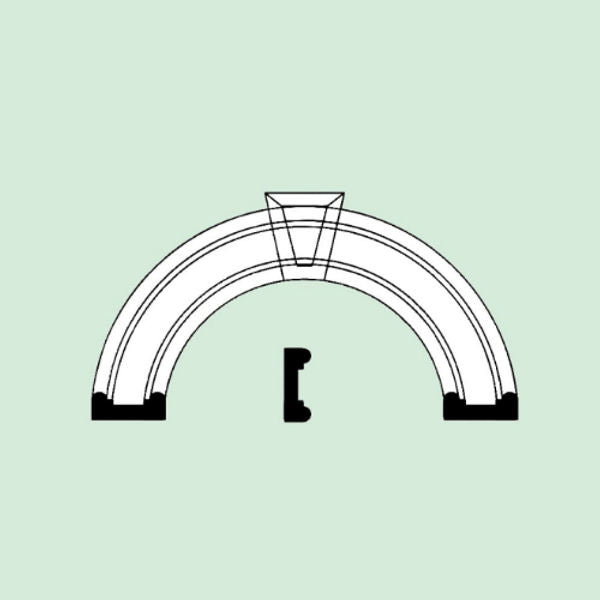

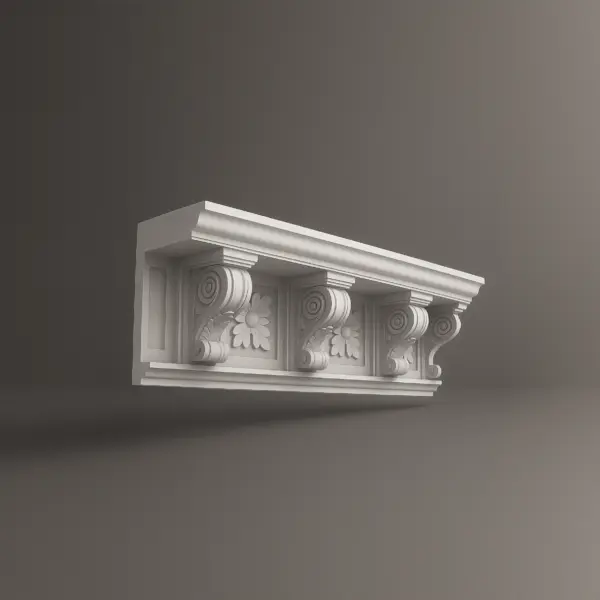

Each decorative arch system consists of precision-made components:

- The Arch: The primary structural form, engineered for perfect curves and crisp lines. Available in any profile you can design, from a subtle decorative wall arch to a soaring entryway.

- The Keystone: The crown jewel of the arch. Our decorative keystones provide the critical finishing touch, available in classic, modern, or completely custom designs.

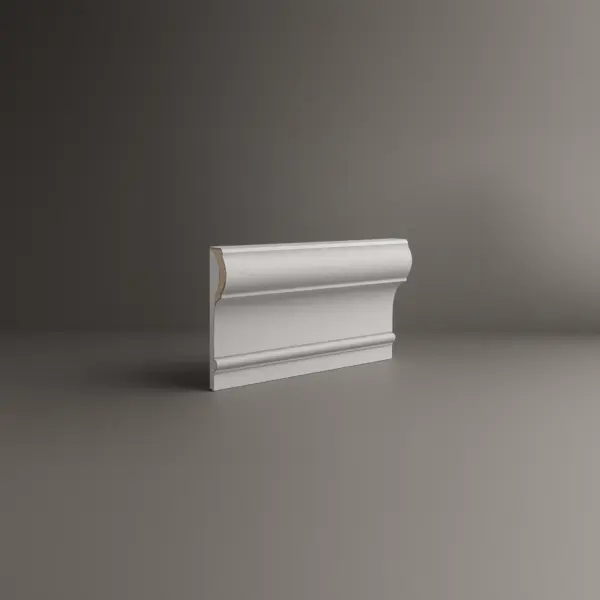

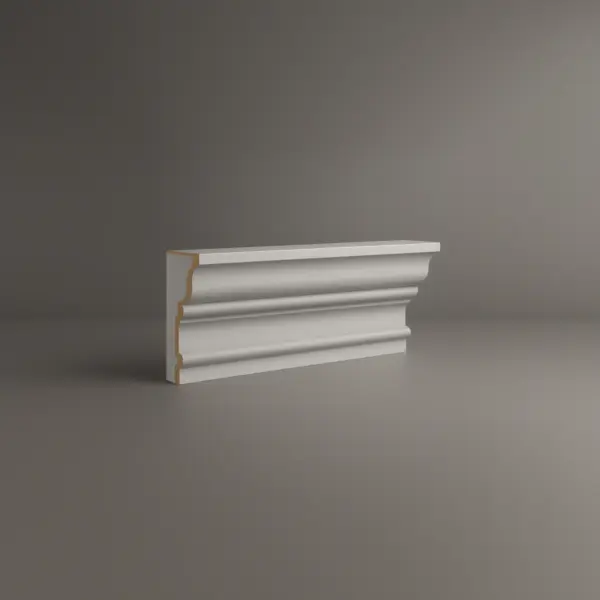

- Supporting Trim & Moldings: Optional elements that integrate the arch seamlessly with the surrounding facade for a fully resolved architectural feature.

Get a modular system that installs with absolute precision, every time.

The science behind flawless form & enduring strength

Our architectural arch systems are built from an advanced composite of materials engineered for a century of performance. At the core is a structural, high-density Expanded Polystyrene (EPS) foam, precision-cut with CNC technology to achieve any geometry your design demands.

This core is then fully encapsulated in our signature polyurea hard coat. This isn’t just a coating; it’s armor. The spray-applied elastomer creates a seamless, waterproof, and impact-resistant shell, transforming the lightweight foam into a monolithic structure with incredible resilience.

The final layer is an integrated, architectural-grade finish that provides the authentic texture of limestone, precast concrete, or any other specified material. This advanced construction makes our decorative arches robust, beautiful, and virtually maintenance-free for 80-100 years.

Assortment of arch & keystone systems

EPS arches vs. traditional masonry:

the Royal Foam advantage

Ready to build without limits?

Stop letting heavy, outdated materials dictate your design. Choose a lightweight, durable, and fully customizable arch system—built to last, made in the USA.

Let's discuss your project today

Discuss my projectMassive & Labor-Intensive

Requires heavy foundations, cranes, and large crews, driving up project costs, timelines, and on-site complexity.

Painfully Slow Installation

Takes weeks due to slow masonry work, mortar curing times, and potential weather delays.

High Maintenance & Vulnerable

Prone to cracking, water damage, and staining. Requires costly and continuous maintenance and repairs.

Severely Limited Customization

Designs are severely limited by material constraints and the extremely high cost of custom carving or formwork.

High Upfront & Long-Term Costs

High upfront costs for materials and labor, plus significant ongoing expenses for repairs and upkeep.

Featherlight & Simple

Up to 90% lighter, eliminating the need for heavy machinery or structural reinforcement and slashing logistics costs.

Rapid installation

Prefabricated system installs in hours, not weeks, dramatically accelerating project completion and minimizing site disruption.

Superior Durability & Zero Maintenance

Waterproof polyurea coat prevents cracking, mold, and rot. Requires zero maintenance for a lifespan of 80-100 years.

Unlimited Customization

Unlimited design freedom. CNC fabrication creates any custom curve, shape, or profile with perfect precision.

Lower Total Cost of Ownership

Lower total installed cost due to massive savings on labor, equipment, transportation, and long-term maintenance.

Сustom arches and keystones

How to order your architectural arches & keystones

From your initial CAD file to final installation—our process is transparent, fast, and engineered for absolute precision.

It all begins with a deep dive into your project. We work as your technical partner to translate creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your decorative architectural shapes with flawless precision, matching your approved 3D model to the millimeter.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exacting standards for form, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build custom shipping crates for your elements, ensuring they arrive on-site in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

It all begins with a deep dive into your project. We work as your technical partner to translate creative intent into a solid, actionable plan.

- Analyze Your Inputs: We review your architectural plans, CAD files, sketches, and inspirational images to understand your design from every angle.

- Define the Scope: In a collaborative consultation, we discuss the project’s aesthetic goals, site conditions, and technical requirements to ensure a perfect fit.

- Establish a Technical Blueprint: We finalize all specifications, from dimensions to finish textures, creating a clear roadmap for fabrication that aligns perfectly with your vision.

We bridge the gap between concept and cost, providing you with the clarity and confidence to move forward.

- Receive a Detailed 3D Visualization: We create and send you a precise 3D model, allowing you to see exactly how your custom architectural elements will look before production begins.

- Get a Transparent, Itemized Proposal: You receive a clear, comprehensive quote with no hidden fees. We believe in total transparency, so you know exactly what you’re investing in.

- Maintain Complete Control for Final Approval: We don’t proceed until you are 100% satisfied. You have the final say on the design and budget before we move to the next stage.

This is where your approved design becomes a physical reality, crafted with an obsessive focus on quality in our 45,000 sq. ft. workshop.

- Execute with Robotic Accuracy: Our state-of-the-art CNC hot-wire machines carve your decorative architectural shapes with flawless precision, matching your approved 3D model to the millimeter.

- Armor for a Century of Performance: Our skilled artisans apply our signature Polyurea hard coat, creating a seamless, impact-resistant, and weatherproof shell designed for decades of durability.

- Verify Through Rigorous Quality Control: Every single piece undergoes a multi-point inspection to ensure it meets our exacting standards for form, finish, and structural integrity.

Our commitment extends all the way to your job site, ensuring a smooth and successful installation.

- Protect with Secure, Custom Crating: We build custom shipping crates for your elements, ensuring they arrive on-site in pristine, ready-to-install condition.

- Streamline Your Installation: Your pieces are delivered pre-assembled and lightweight, designed to slash on-site labor time and eliminate the need for heavy machinery.

- Support Your Crew to the Finish Line: We provide detailed installation guides and offer live Zoom support to answer your team’s questions, guaranteeing a perfect final fit.

Our project gallery

Engineered solutions for every vision

From commercial landmarks to luxury residences, we provide the tailored architectural solutions that bring professional visions to life.

For Architects & Designers

Achieve the designs you were told weren’t feasible. We fabricate custom decorative arches to your exact CAD specifications, from historically accurate replications to daring contemporary forms. We provide the technical partnership you need to realize your vision without compromise.

For Developers & Builders

Make your entrance unforgettable. A grand archway communicates permanence and prestige, elevating your brand for hotels, corporate campuses, banks, and retail centers. Our low-maintenance solutions are built to impress in high-traffic environments.

For Commercial Properties

Make your entrance unforgettable. A grand archway communicates permanence and prestige, elevating your brand for hotels, corporate campuses, banks, and retail centers. Our low-maintenance solutions are built to impress in high-traffic environments.

For Luxury Homeowners

Create a statement entrance that defines your home’s character. Whether it’s a series of decorative garden arches or a majestic front entryway, our systems deliver the look and feel of solid stone with a faster, cleaner, and more cost-effective process.

Before and after:

a strategic transformation

Discover our workAn arch is more than an entrance—it's a statement

An entryway arch is the first and last thing your clients and visitors experience. It does more than frame a door; it frames their entire perception of your brand. A well-engineered arch instantly communicates authority, elegance, and attention to detail.

- Communicate Prestige and PermanenceA solid, monolithic arch adds an immediate sense of history and stability. It demonstrates an investment in quality that builds trust and credibility with clients, partners, and investors before they even walk inside.

- A Durable, Low-Maintenance AssetForget about cracking mortar or weather-stained concrete. Our arch systems are engineered with a polyurea shell to withstand harsh weather, UV rays, and time—staying beautiful for decades with virtually no maintenance. This low total cost of ownership is a smart financial decision for any property owner.

- Custom Design for Your Brand IdentityYour architecture is part of your brand. Our ability to create any shape, size, or finish means your entryway can be perfectly tailored to your brand's identity, whether it's classical and reassuring or modern and innovative. We can even integrate decorative keystones with logos or emblems.

Voices of our clients

From your first idea to the final installation — our process is clear, fast, and designed to make every detail simple.

FAQ

- How fast is installation?

Usually about 165–190 linear feet in four workdays. On a particularly tight downtown site, an entire run was installed with just a small crew and no heavy equipment — and still finished ahead of schedule.

- Will it feel quieter next to a busy road?

Absolutely. Most people notice the difference the first evening. The shell reflects harsh noise while the foam core absorbs the rest. At a project near a Miami expressway, the change was dramatic enough that residents started using their outdoor space again.

- Can you match our façade color exactly?

Yes — we’re obsessive about that. Foam takes acrylic with precision, and we routinely achieve perfect visual matches. A historic property in Savannah once had us match an aged brick tone, and even the neighbors assumed the new wall was original masonry.

- What if we have a big grade change?

No problem. Foam follows contours far more easily than concrete or masonry. Instead of awkward steps, we can create smooth transitions that maintain visual calm and proper drainage.

- Will a white finish last in coastal weather?

It will if the system is specified correctly. With the right coating and finish, walls along the Gulf Coast have stayed chalk-free and color-true for years. Occasional rinsing is usually all the maintenance required.

- Are foam panels strong enough for high winds?

Yes. When everything is engineered thoughtfully — from precise anchor spacing to slightly shortened modules in the most exposed spots — the fence doesn’t behave like a fragile structure, but like a seasoned sailor standing firm on deck in the middle of a storm. Even hurricane-level coastal winds don’t faze it: it doesn’t shift a millimeter, doesn’t crack, and never gives in to the elements. At one property near Daytona Beach, the fence looked as if it had been installed yesterday, even after an entire storm season — perfectly straight, steady, and untouched. It’s more than just strength; it’s a quiet confidence you can feel when you look at it, as if the architecture itself is saying, “I’m right where I belong — and I’m not going anywhere.”

- Can we include a recessed logo without a billboard look?

Definitely. Because foam is so easy to shape, recessed details feel purposeful rather than forced. One Atlanta property incorporated its logo into a shadowed niche with subtle lighting — the effect is elegant by day and welcoming at night.

- Is six feet high enough for privacy?

Often, yes. Especially when paired with strategic planting. And if local codes require more, we can add height without creating a fortress-like presence.

- What do you need to provide a quote?

Length, height, a style cue, and a few photos. Include a color sample early and we can return strike-offs with the estimate — speeding approvals by up to a week.

- We want a wood look without the upkeep.

We can achieve that easily. Slim aluminum fins paired with textured foam surfaces create the warmth and light play of wood without rot, refinishing, or fading. On one residential project, the “wood” still looked fresh three seasons later with nothing more than a garden hose rinse. The result was as visually appealing as natural wood and perfectly matched the desired look of the homeowner.

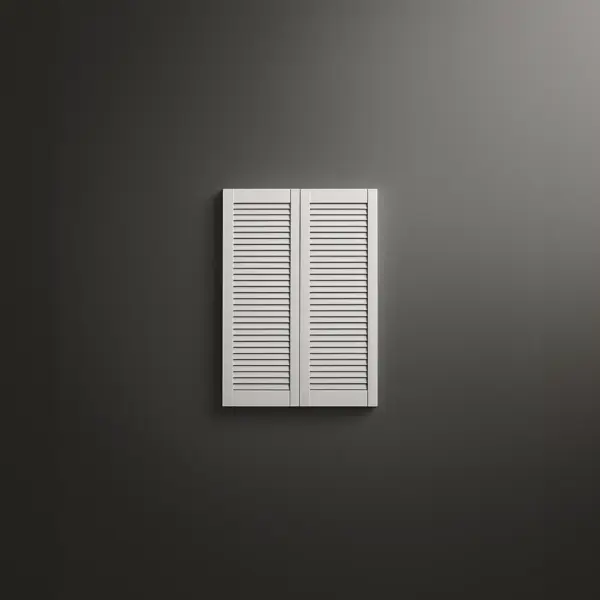

Your essential design & spec catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Let's build something great together

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!

More our solutions

We provide architects, builders, and homeowners with turnkey decorative elements that transform any project — fast, easy, and cost-effective.

Blog posts

Ready-made facade elements with factory assembly. Fast installation, fewer errors, and reduced costs.

Construction companies

Developers

Standardized solutions for neighborhoods. Quick delivery, unified style, no downtime.

Architects and designers

Сustom solutions for the project: 144+ textures, any shapes,

and technical documentation.

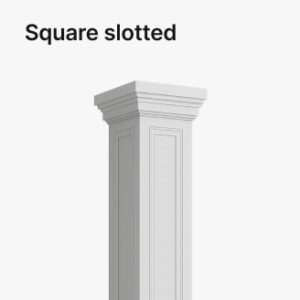

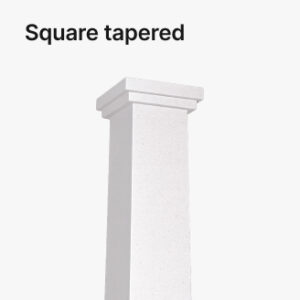

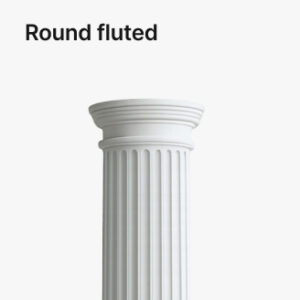

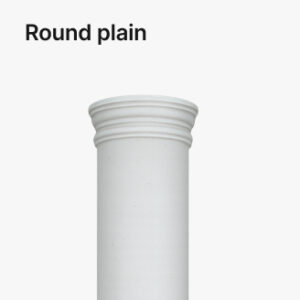

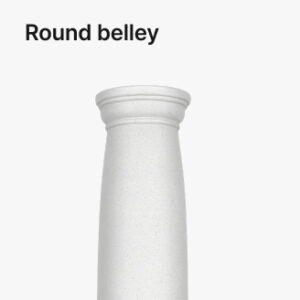

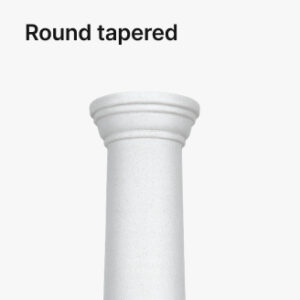

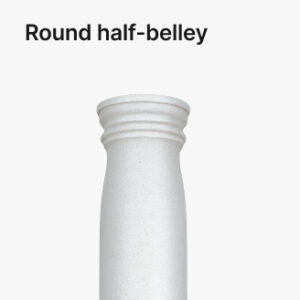

Architectural columns

In construction, the little things are never little. Schedules slip on half-days, margins evaporate on “almost” fits, and a great design can fall flat if the façade reads cheap or unfinished. Columns do a quiet kind of heavy lifting: they frame entrances, set rhythm and scale, and signal intent before anyone steps inside. With a wooden beam hidden in their core, they don’t just support a roofline — they support brand perception, leasing velocity, and long-term value.

We build every column from foam — on purpose. Not as a shortcut, not as a budget hack, but because we’ve learned in the field that foam is the 21st-century material that lets design and construction finally pull in the same direction. It’s light enough to keep logistics sane, tough enough to take weather for decades, and flexible enough to deliver profiles you can’t reasonably get in stone or precast without blowing the schedule. And the finish? We’ve had inspectors tap our “stone” shafts in disbelief. That’s the point: all the beauty, none of the baggage.

Where architectural columns start paying you back

Custom foam architectural columns aren’t just decoration.

They’re business decisions dressed as design.

They upgrade how a building reads from the street, which nudges rents and conversion rates the right way.

They help reconcile tricky proportions — taller openings, deeper porches, longer frontages — into a cohesive, deliberate façade.

They compress install time: an exterior refresh with exterior columns will move the needle faster than almost any other single intervention.

They keep schedule risk low. A lightweight system eliminates cranes, lane closures, and half the headaches that trigger change orders.

One retail strip in Naples, FL was struggling with vacancy and visual appeal. The brief sounded simple — “make it look premium and do it fast.” Precast quotes came back with eight-week molds and weekend crane windows. We engineered a run of large columns with foam cores and polymer-cement skins and swapped in modern architectural columns at the corner bays. Installation took just four days, there were no street closures, and two anchor tenants renewed leases before the punch list was even closed. That’s how design becomes a revenue tool.

A fast detour through history (that still matters on site)

Columns have been the architectural handshake for millennia. The Greeks gave us the Greek Doric column, Ionic column, and Corinthian column — the original design system. Romans supersized them, added Tuscan style, and the Renaissance tuned proportions until facades felt like music. Modernism stripped them back to essential geometry, and late-20th-century construction taught us to separate look from load.

We build on all of that. It’s why our catalog spans types of columns from strict classical to razor-clean modern. Foam lets us honor the lineage — entasis, fluting, capitals, plinths — while building for today’s realities: tight sites, firm budgets, and immovable go-live dates.

Why foam wins (engineer to engineer)

Let’s talk mechanics, coatings, and field behavior — the stuff that actually decides whether a project lands cleanly.

- Core and density. We use high-stability EPS tailored to the profile: denser for crisp fluting and tight radii, lighter for oversized cladding. Shafts are CNC-cut for millimetric repeatability.

- Reinforcement. For structural applications (most architectural porch columns), foam columns are manufactured in halves with a cutout for structural wood post or aluminum pole hidden inside. For decorative outdoor columns, the foam shell with a hard coat is usually enough.

- Coatings and finishes. Impact-resistant, UV-stable, hydrophobic topcoats. From “warm limestone” to “coral travertine,” from deep flutes to board-formed textures. Exterior stucco columns get elastomeric finishes tuned for coastal UV and salt.

- Joints and movement. We specify concealed expansion breaks on long runs, flexible sealants at interfaces, and breathable coatings to manage vapor without blistering.

- Life cycle. Foam is inert (no rot, no rust, no spall), and the shell resists hairline cracking. Typical maintenance: rinse, inspect seals, optional repaint every few years. TCO stays predictably low.

Our approach has been tested even in hurricane-rated zones. Modern stucco columns with internal posts and through-base anchoring have survived storms that sandblasted nearby finishes. That’s not marketing — that’s field performance.

Design spectrum: from colonnades to one perfect porch

There isn’t one “right” column — there’s the right column for this building.

- Classical sets. Doric columns for gravitas, Ionic columns for refinement, Corinthian columns for a little drama. Perfect for banks, civic buildings, and clubhouses.

- Transitional mixes. Composite capitals on clean shafts, or modern entasis paired with traditional bases — a sweet spot for hospitality and multifamily.

- Modern architectural columns. Pure cylinders, crisp rectangles, chamfered squares — zero fuss, maximum impact.

Large porch columns. Oversized, calming proportions for residential entries or leasing offices that make smaller structures feel substantial. - Stucco columns and foam columns for stucco. Essential when you need texture continuity with EIFS/stucco façades or a patio cover with stucco columns that ties the outdoor space into the main structure.

A resort near Fort Lauderdale once came to us with an unusual request: they wanted interior columns for a double-height lobby and matching exterior elements under a porte-cochère. We matched the geometry across both, concealed linear LEDs within the reveals, and transformed the night elevation into something magazine-worthy — without a single crane day.

How our columns are installed (and why it matters)

We ship columns ready for a straightforward, low-drama installation process.

Simply glue column shafts, capitals and bases around the structural post with an adhesive that doesn’t contain acetone, and caulk the seams. We provide touch up paint to finish the job. For the heavier capitals, secure them with temporary wrapping overnight while the adhesive cures.

Most residential projects with four to six outdoor columns finish in two days. Commercial installations with a dozen exterior stucco columns rarely exceed a week. No cranes, no lane closures, no chaos — and no budget overruns.

A story of the impossible made real

Atlanta, creative campus, new headquarters for a media company. The design called for a sculptural drive-through portal — a procession of towering columns forming a modern triumphal arch. The precast was too heavy. Steel cladding is too cold and too expensive. Our solution: a series of modern stucco columns, 30 inches in diameter and 22 feet tall, each a foam shell around a hidden steel spine with a deep limestone finish.

We integrated signage and halo lighting into the capitals, with concealed service access. The entire structure was installed in 72 hours between two rainstorms. The client’s team walked the site at dusk and simply stopped. “This is exactly what we imagined.” The arrival sequence felt elevated, the architecture purposeful. That’s what happens when material, design, and engineering pull together.

Cost, TCO, and the numbers that make sense

Installed costs typically land 50–70% below stone or precast once you factor in freight, rigging, and finish cycles. But the bigger win is predictability:

- Shipping: More on a truck, fewer trips, lower rates.

- Labor: Smaller crews, shorter install windows, less staging.

- Maintenance: Occasional rinsing and seal checks — repaint when branding changes.

- Risk: Fewer unknowns, fewer trade conflicts, fewer surprises.

Developers appreciate the math. Contractors love schedules that don’t slip. Owners value façades that still look crisp a decade later. And if you have a project coming up — whether it’s a portico, a perimeter, or a full façade rethink — talk to us early. We’ll translate sketches into shop drawings, produce samples you can hold, and deliver columns that feel like they’ve always belonged there.

Your essential design & spec catalog

Get the definitive guide to our custom decorative architectural foam shapes. This free catalog is packed with hundreds of design profiles, detailed technical specifications, and real-world project applications.

Let's build something great together

Have a project in mind?

Our dedicated specialists are ready to collaborate with you, turning your concept into a detailed plan with a transparent budget. Let’s bring your vision to life!