Why foam is the smartest choice — and how we engineer it

We work exclusively with foam — and in our view, that’s one of the best decisions we’ve ever made. It’s not about trends or shortcuts; it’s the result of decades of testing, problem-solving, and lessons learned on real job sites. Over and over again, foam has proven itself superior to stone, concrete, and wood where it matters most: strength without unnecessary weight, creative freedom without runaway costs, and consistency without the headaches that used to keep project managers awake at night.

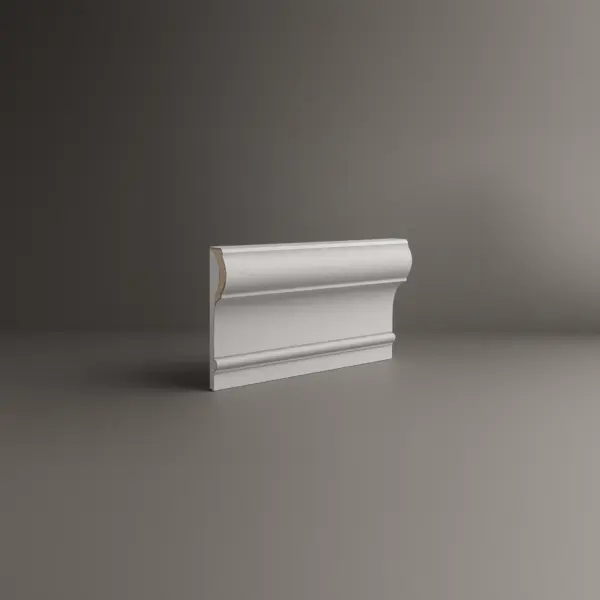

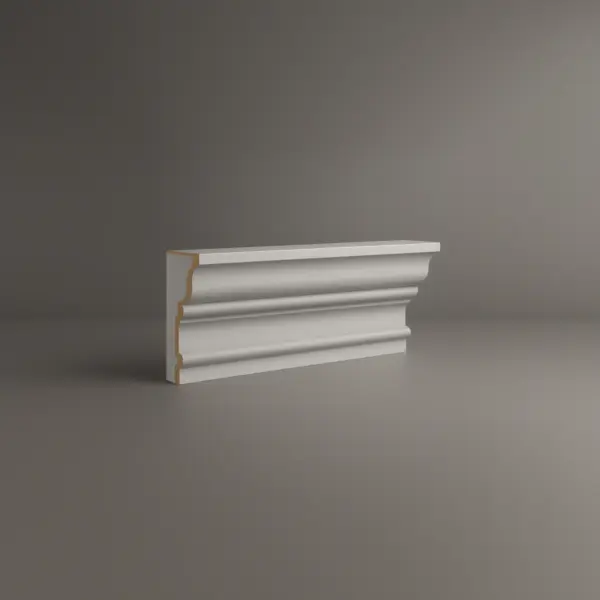

Core and density

We use high-stability EPS (typically 1.5–2.0 lb/ft³), which ensures precise geometry during CNC cutting. Because foam is so light, it barely adds any load to the structure — think of it as dressing the building instead of weighing it down. That reduced weight drastically cuts the demand on the structural framework and anchoring system, which isn’t just convenient but critical in retrofit projects or mid-rise commercial builds, where every extra pound affects budgets and safety margins.

Protective coatings

Each profile is coated with a next-generation, fire-rated polyurea hard coat. This creates a tough, impact-resistant shell that shrugs off weather, UV, and mechanical stress. In coastal zones like Miami, an application of concrete sealer topcoat protects against harsh marine environments and maintains performance for decades.

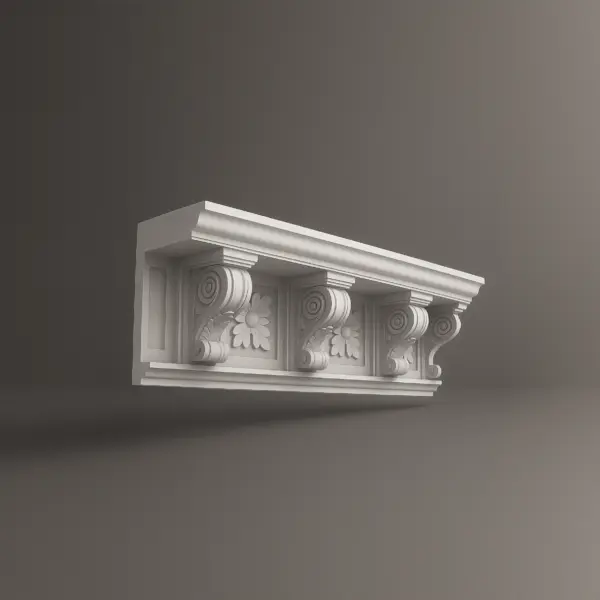

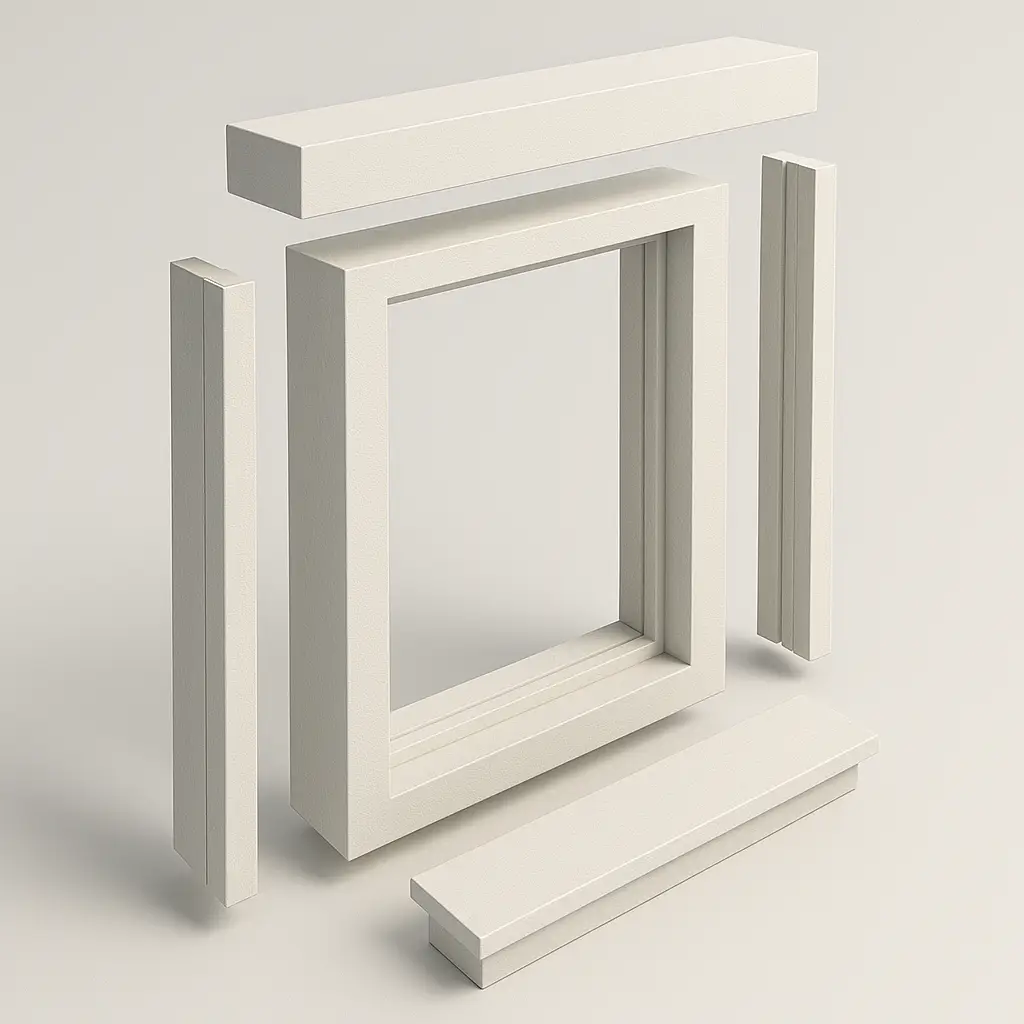

Custom textures and finishes

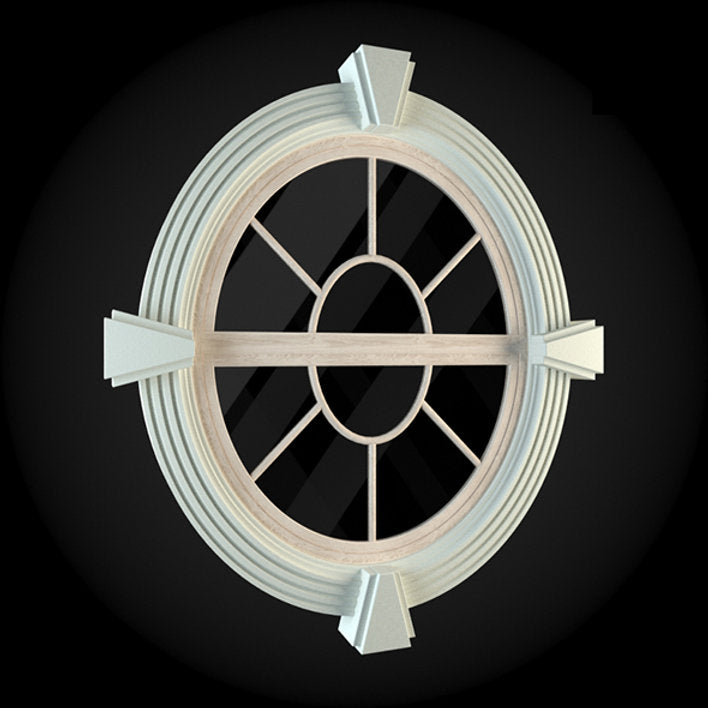

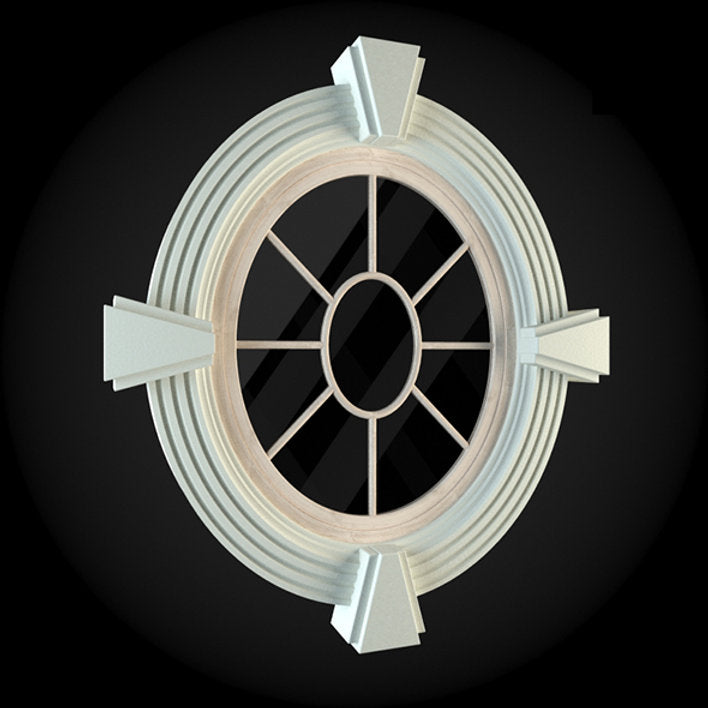

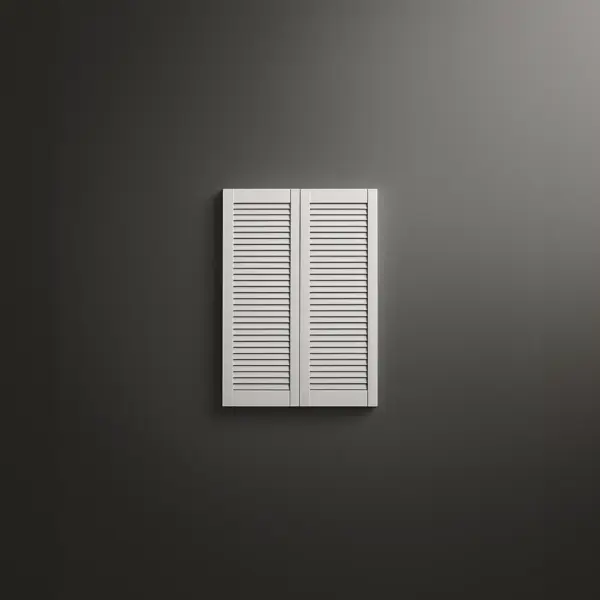

Foam is a true chameleon. It can be shaped and finished to mimic nearly any material:

- Stone: Porous, chiseled, and weathered — visually identical to limestone or travertine.

- Concrete: Smooth, pitted, and industrial — replicating the raw aesthetic of poured cement or precast blocks.

- Wood: Grainy, knotted, and rough-hewn — indistinguishable from heavy timber or reclaimed barn wood.